Winding Operator (6 Month Diploma)

Winding Operator (6 Month Diploma)

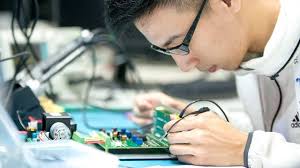

Winding Operator: The Winding Operator winds film or wire on core using

automated or semi-automated winding machines for manufacturing

capacitors or resisters.

Brief Job Description: The individual at work operates the semi-automated or

programmed winding machine to wind metal-alloy wire or metalized film on

to a core in the process of manufacturing a resister or capacitor. The

individual also sample checks the resistance or capacitance of the winding.

Personal Attributes: The job requires the individual to have: steady hands,

ability to concentrate and work in a steady position for long hours.

Undertaking preventive maintenance

To be competent, the user/individual on the job must be able to:

PC17. perform regular cleaning of machine, equipment and work area as prescribed

by machine manufacturer using air hoses, cleaning fluids and hand tools

PC18. check tension control, core settings and sensors, and synchronise rollers

PC19. follow machine stop time as prescribed

PC20. detect for any damage or defects and maintain machine

Achieving

productivity and

quality standards

To be competent, the user/individual on the job must be able to:

PC21. achieve 100% target number to be wound as per program or instructions

PC22. ensure defective windings are within specified range

PC23. ensure symmetrical winding

PC24. document the outcome of winding performed and report to superior

PC25. achieve zero unscheduled machine down time

PC26. deliver to the next stage on time

Knowledge and Understanding (K)

A. Organizational

Context

(Knowledge of the

company /

organization and

its processes)

The individual on the job needs to know and understand:

KA1. company’s policies on: incentives, delivery standards and personnel

management and Intellectual Property Rights (IPR)

KA2. work flow involved in production process of the company

KA3. importance of the individual’s role in the workflow

KA4. reporting structure

KA5. profile of clients

KA6. raw material stocking standards

KA7. safety and quality standards followed in the organization

B. Technical

Knowledge

The user/individual on the job needs to know and understand:

KB1. basic electronics and component identification

KB2. practical examples and applications of different types of passive components

KB3. basic electrical, AC / DC voltage, contactors and fuses

KB4. different types of resisters and capacitors, their properties and application

KB5. types of winding machines and their parts such as bearing, mandrel, shafts,

spools, rollers, sensors, safety mechanism

KB6. importance of alignment and balancing

KB7. basic programming, setting up and loading of the machines

KB8. different types of winding processes

KB9. test and measuring instruments for testing various parameters of capacitors

and resistors and variance

KB10. colour codes and polarity of resistors

KB11. raw materials, e.g., type of wire or film used and their properties such as

break down voltage, metalizing process

KB12. production processes, quality control, costs

KB13. FIFO system of inventory control

KB14. handling of raw materials

KB15. traceability back to original materials

KB16. routine maintenance of machines and basic repairs

KB17. 5S standards (sorting, setting, standardise, sustain, shining) + safety, security

KB18. commonly occurring machine and component defects