Final Assembly Operator-Magnetics ( 6 Month Diploma)

Final Assembly Operator-Magnetics

Final Assembly Operator-Magnetics: The Final Assembly Operator-Magnetics

is responsible for completing the assembly of wound coils on lamination for

SMPS transformer, lighting coil or chokes.

Brief Job Description: The individual at work fills the core, tapes and tests the

assembly, applies varnish, marks and packs.

Personal Attributes: The job requires the individual to have: steady hands,

ability to concentrate and work in a steady position for long hours.

Assemble the magnetic component

Description

This OS unit is about filling the core, testing the assembly, varnishing it, printing and

packing

Scope

This unit/task covers the following:

Understand the work requirement

Fill the core, tape and test the assembly

Apply varnish to tested assembly

Achieve productivity and quality of standards

Performance Criteria(PC) w.r.t. the Scope

Element Performance Criteria Understanding work requirement

To be competent, the user/individual on the job must be able to:

understand the day’s work target from superior

read the job sheet for product type, number, run shifts

collect the winding and core or lamination in quantities required

understand the material handling and dust free requirements

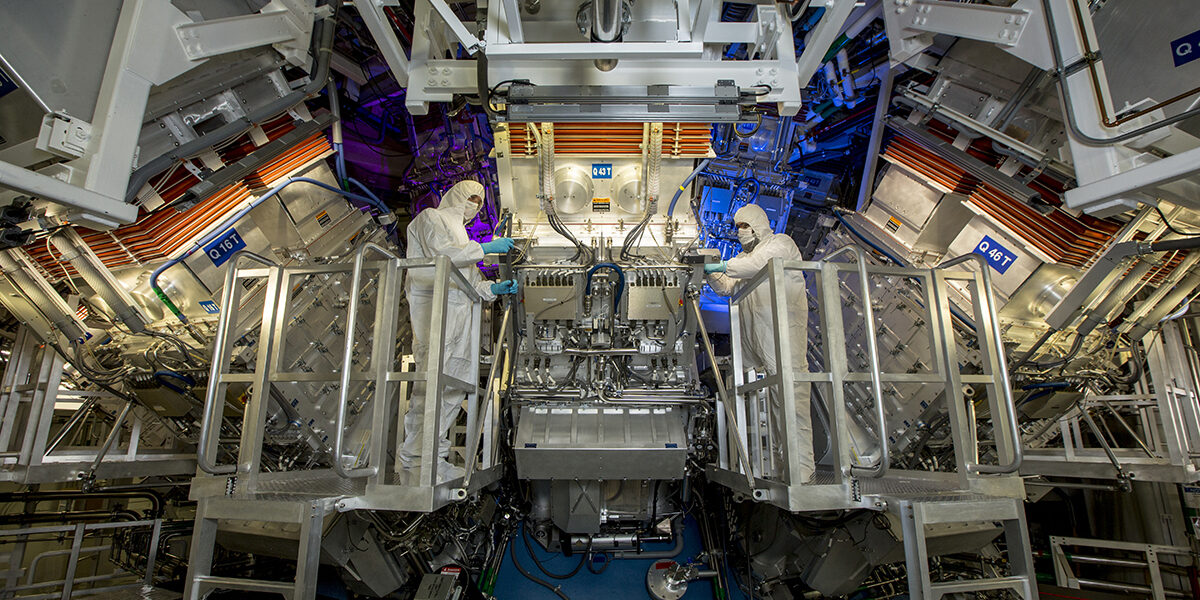

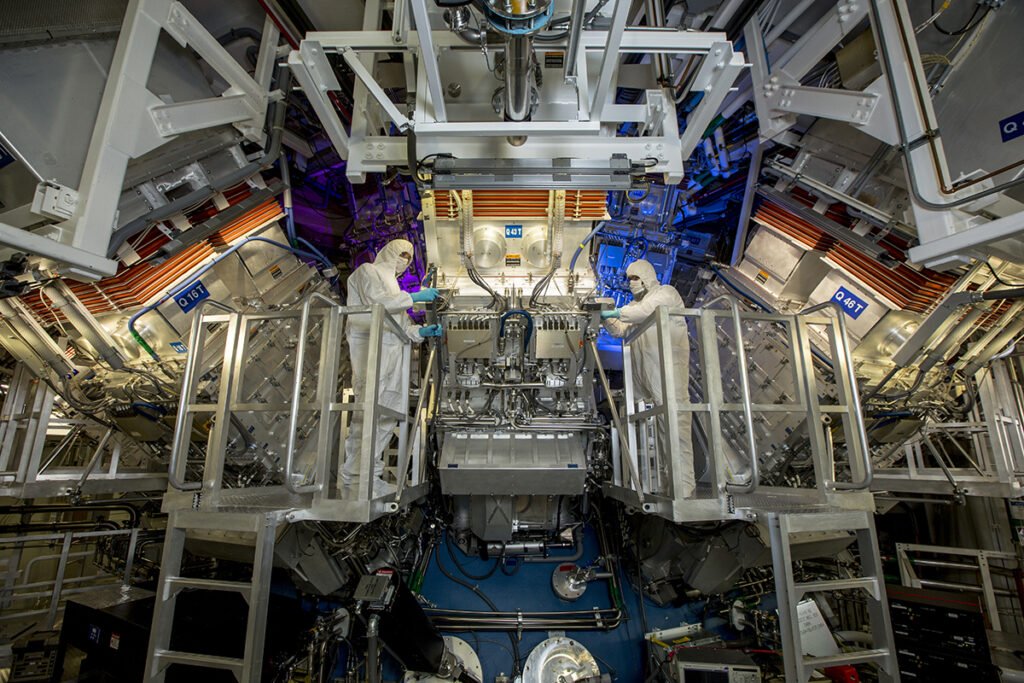

Filling core, taping and testing magnetic component assembly

To be competent, the user/individual on the job must be able to:

insert the core or lamination on winding bobbin

tape the winding and core assembly

select the jig for testing as per company’s specifications

fix the winding and core assembly on the jig

test the assembly using analyser machines, e.g., transformer analyser

assess failure causes, e.g., high voltage, leakage

note recurring problems

record the number of failed pieces

maintain ambient temperature, humidity, contamination and dust free

environment as per company’s policy

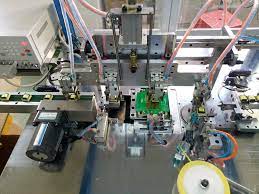

Varnishing winding and core assembly, marking and packing

To be competent, the user/individual on the job must be able to:

apply weather coat varnish to assembly

dip coil in varnish, not the pins as per instructions

check coating thickness ad viscosity of varnish

cure in oven at specified temperature and for specified duration

use stamping machine or ink-jet printer to print on the component details

such as company name, product specifications, lot size, manufacturing date

dry using specified methods such as UV lamp or in ambient temperature

check visually for straight pins, damage, soldering of terminals and marking

pack the component as per company’s policy

Achieving productivity and quality standards

To be competent, the user/individual on the job must be able to:

achieve 100% target number to be assembled

ensure defective assembly are within specified range

Follow safety standards

Description

This OS unit is about following safety procedures, communicating potential hazards

and dangers of accidents on the job

Scope

This unit/ task covers the following:

Understand potential sources of accidents

Use safety gear to avoid accidents

Understand the safety procedures followed by the company

Performance Criteria(PC) w.r.t. the Scope

Element Performance Criteria

Understanding potential sources of accidents

To be competent, the user/individual on the job must be able to:

spot and report potential hazards on time

follow company policy and rules regarding hazardous materials

avoid accidents related to use of potentially dangerous chemicals, gases,

sharp tools and hazards from machines which involves exposure to possible

injuries such as cuts, bites, stings, minor burns, etc.

Handle with care when using an electrical drill and sharp cutting objects

Using safety gear To be competent, the user/individual on the job must be able to:

understand which safety gear must be used for a particular task

eye, respiratory and hearing protection as per company policy

use safety gear such as respirator, mask, skull caps, gloves, goggles, jacket ,

etc., as prescribed for the job

Understanding of safety procedures

To be competent, the user/individual on the job must be able to:

comply with standard health and safety procedure followed in the company

while handling an equipment and hazardous materials and tools or situations

understand and follow the evacuation procedure properly such as fire drills,

emergency evacuation procedures, first aid to self and others, etc., which

help in case of an emergency Following daily safety measure

To be competent, the user/ individual must be able to:

take adequate safety measures while on work to prevent accidents

ensure zero accidents in work

avoid damage of components due to negligence in ESD procedures

ensure no loss for company due to safety negligence

ensure proper machine maintenance, work process achieving quality outputs

as per the company standard

Communicating to supervisor

To be competent, the user/ individual must be able to:

improve process flow to reduce anticipated or repetitive hazards

report on mishandling of tools, machines or hazardous materials and on

electrical problems that could result in accident

escalate about any hazardous materials or things found in the premises

report about any breach of safety procedure in the company

follow electrostatic discharge (ESD) measures for electronic component

safety