Cutting, Crimping and Connector Assembly Operator(6 Month Diploma)

Cutting, Crimping and Connector Assembly Operator

Cutting, Crimping and Connector Assembly Operator: The Cutting, Crimping

and Connector Assembly Operator is responsible for cutting wire or manually

or using machine, crimping wire and assembling wire into the housing.

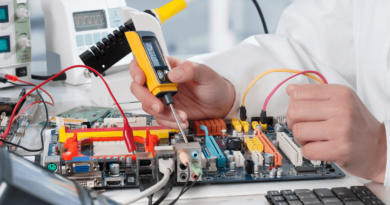

Brief Job Description: The individual at work operates the cutting machine,

crimping machine and manually cuts wire and completes connector assembly.

The individual is also responsible for checking quality of connector assembly.

Personal Attributes: The job requires the individual to have: steady hands,

ability to concentrate and work in a steady position for long hours.

Cut wire, crimp pins and assemble connector

This OS unit is about cutting wire manually or using machine, crimping pins on wire

using machine and assembling wire into connector housing and checking assembly

Scope

This unit/task covers the following:

Understand the work requirement

Cut wire using machine or manually

Crimp pins on wire manually or using machine

Assemble wire in connector and check

Achieve productivity and quality of standards

Performance Criteria Understanding work requirement

To be competent, the user/individual on the job must be able to:

understand the day’s work target from superior

read the job sheet for product type, number, run shifts

understand the material handling and dust free requirements

Cutting wire

To be competent, the user/individual on the job must be able to:

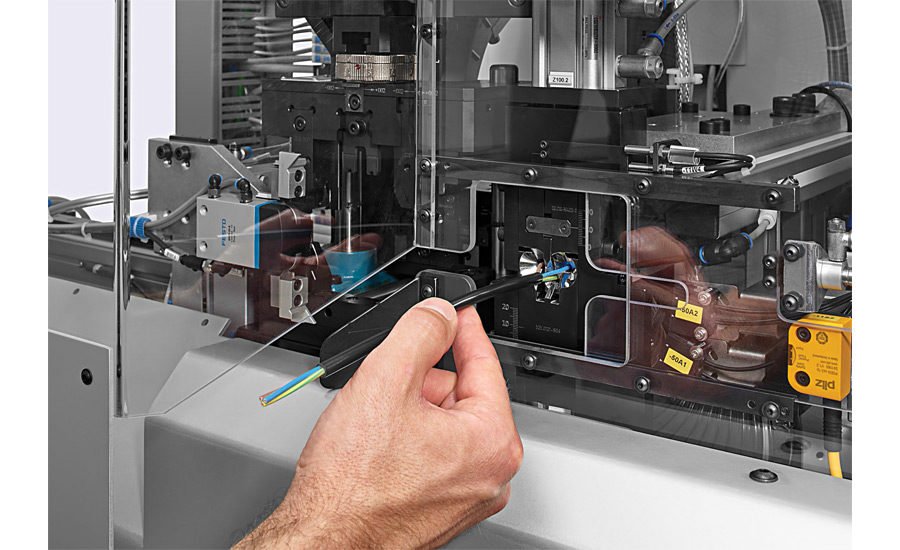

program the cutting machine for wire type and length of cut and insulation

stripping

insert wire in machine and run the cutting program

ensure that wires do not get bunched up

cut and strip wire manually as per instructions on length of cut

check wire cutting for consistency and conforming to standards

maintain ambient temperature, humidity, contamination and dust free

environment as per company’s policy

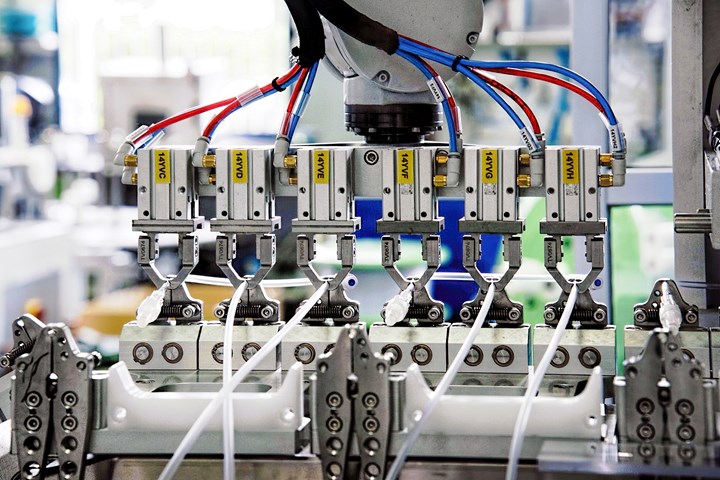

Crimping pins

To be competent, the user/individual on the job must be able to:

use hand and leg combination to press machine for crimping wire

ensure that wastage is minimum

check combination of single side or double side crimping as per drawing

check visually for straight and damage-free pins

maintain ambient temperature, humidity, contamination and dust free

environment as per company’s policy

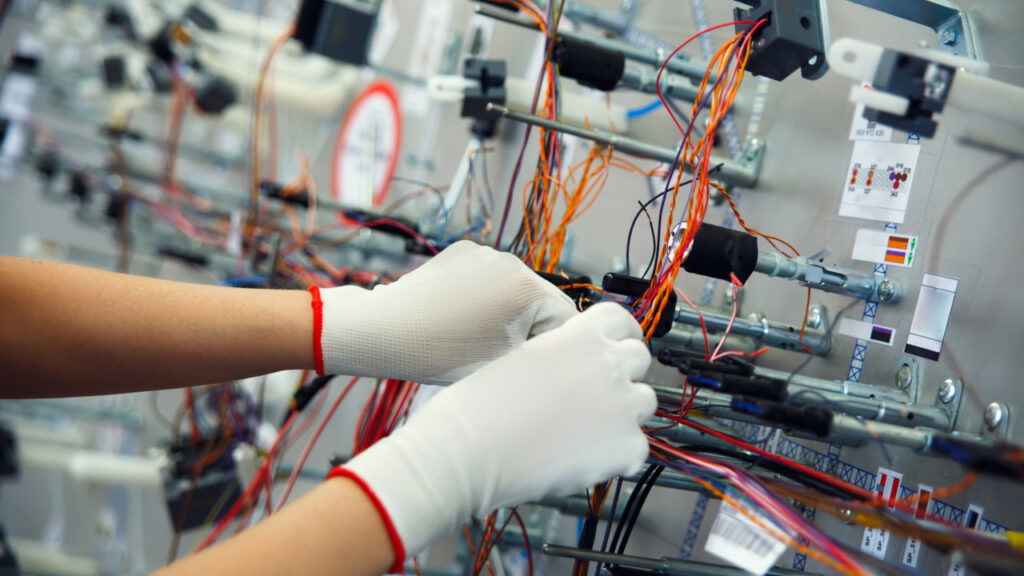

Assembling connector

To be competent, the user/individual on the job must be able to:

use certified and cut wire

insert wire into housing manually and lock

check for loose wiring or crimping or wrong combinations

Achieving productivity and quality standards

To be competent, the user/individual on the job must be able to:

achieve 100% target number to be assembled

achieve zero rejects

Organizational Context

The individual on the job needs to know and understand:

company’s policies on: incentives, delivery standards and personnel

management and quality

work flow involved in production process of the company

importance of the individual’s role in the workflow

reporting structure

profile of clients

raw material stocking standards

safety and quality standards followed in the organization

Technical Knowledge

The user/individual on the job needs to know and understand:

basic electronics and component identification

different types of cables and wires

machine programs and operations for cutting and crimping

wire combinations and housing assembly

ISO standards

FIFO system of inventory control

handling of raw materials

traceability back to original materialsroutine maintenance of machines and basic repairs

5S standards (sorting, setting, standardise, sustain, shining) + safety, security

commonly occurring machine and component defects

Skills (S) [Optional] Core Skills/ Generic Skills

Reading and Writing Skills

The user/individual on the job needs to know and understand how:

to maintain job sheet, logs and records

to operate computer and machine

to read production schedules and operations manuals

to document the outcome

Communication Skills

The user/individual on the job needs to know and understand how:

to effectively communicate with the supervisor on the process issues

to effectively communicate maintenance issues to the maintenance personnel

Team work and Multitasking

The user/individual on the job needs to know and understand how:

to be able to work on multiple lots at a time, as instructed

to work as a team and deliver on time to next work process

Professional Skills Reflective Thinking

The user/individual on the job needs to know and understand how:

to reduce repetitive errors

to improve work process

Cut wire, crimp pins and assemble connector

Analytical Thinking

The user/individual on the job needs to know and understand how:

to promptly resolve problems

to enhance machine performance

Using Test instruments and Machines

The user/individual on the job needs to know and understand how:

to operate the transformer analyser machine

to operate cutting and crimping machine

Critical Thinking

The user/individual on the job needs to know and understand how:

to spot process disruptions and delays

to interpret instructions furnished in written, oral or schedule form

Problem solving and Troubleshooting

The user/individual on the job needs to know and understand how:

to identify and resolve problem during crimping and cutting process

. to troubleshoot and rectify mechanical problems and reduce unscheduled

down time

Work with superiors and colleagues

Description

This OS unit is about communicating, coordinating and maintaining proper

relationship with colleagues and seniors in order to achieve smooth work flow

Scope

This unit/ task covers the following:

Interact with supervisor or superior

Coordinate with colleagues

Performance Criteria(PC) w.r.t. the Scope

Element Performance Criteria

Interacting with supervisor

To be competent, the user/ individual must be able to:

understand work requirements by receiving instructions from reporting

supervisor

understand standard operating procedure of the company

escalate problems that cannot be handled including repetitive PCB defects,

machine failures, potential hazards, process disruptions, repairs and

maintenance of machine

report work completed and receive feedback on work done

resolve personnel issues

rectify errors as per feedback and minimize mistakes to zero in future

communicate about process flow improvements, quality of output, product

defects received from previous process, repairs and maintenance of tools and

machinery as required and find technical solutions on specific issues

handover completed work and deliver the work of expected quality despite

constraints Interacting with colleagues

To be competent, the user/ individual must be able to:

collect required spares and raw materials from tool room or stores

deposit unused or faulty materials, parts and tools to stores

assist colleagues where necessary and as per capability

resolve conflicts with colleagues at work to achieve smooth workflow

complete rework in time based on feedback from quality or process

departments

put team over individual goals

Knowledge and Understanding (K)

Organizational Context

The individual on the job needs to know and understand:

company’s policies on: incentives, delivery standards, and personnel

reporting structure