Welding Operator(6 Month Diploma)

Welding Operator(6 Month Diploma)

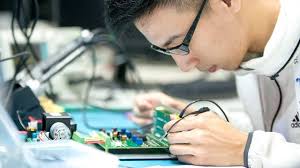

The Welding Operator welds the copper lead wire to the resistor using welding

machine.

Brief Job Description: The individual is responsible for welding the electro-tinned

copper lead wire to the centre of steel and cap, bonding to the resistor by welding

machine.

Personal Attributes: The job requires the individual to have attention to details and

ability to work for long hours generally in a sitting position.

Weld the copper lead wire to resistor (WELDING-OPERETAR)

This OS unit is about welding the electro-tinned copper lead wire to the centre of steel

and cap, bonding to the resistor by welding equipment as per specifications.

This unit/task covers the following:

• Understand the work requirement

• Set up and operate the welding equipment

• Check visually on the welding quality

• Undertake preventive maintenance of welding equipment

• Achieve productivity and quality of standards

To be competent, the user/individual on the job must be able to:

. collect the required materials and equipment for welding

. record the number received

read the job sheet to for specifications of the lot received

assess welding parameters such as temperature, pressure, electrode type,

electrode distance or gap, welding current, voltage, process time, etc.

compare the thickness of copper wire, filler material and flux required for

welding process

program operating instructions into the computers to adjust and start

welding machine

install welding work pieces to the welding machine aligning in a way that

work pieces do not turn or fall down

add chemicals to work pieces to ensure bonding

fix work pieces such as grinder, cutter, drills and flux into welding machine

set the machine based on size of cap and load on the machine

insert the lead wire through the hole provided in the top plate of the upper

moving portion above the welding electrode

push the wire until it comes out of the bottom of the upper moving portion

set the variance and voltage depending upon the cap size

choose and fix the bottom electrode according to cap size

adjust welding heads and tooling according to work specifications

place the materials onto the machine

operate the welding machine as specified in work order to weld the electro

tinned copper lead wire to the centre of steel and cap

remove completed work pieces from the machine using handling tools

monitor the machine constantly to obtain desired weld

check gauge, dials, and other indicators of the machine

Work with superiors and colleagues

how to communicate effectively

how to build team coordination

Writing Skills

The user/ individual on the job needs to know and understand how to:

Complete forms such as work orders, invoices, maintenance records

note problems on job sheet and details of work done

Reading Skills

The user/ individual on the job needs to know and understand how to:

read warnings, instructions and other text material on product labels,

components, etc.

read job sheets or work orders

read product and module serial numbers and interpret details such as make,

date, availability

Oral Communication (Listening and Speaking skill)

The user/ individual on the job needs to know and understand how to:

receive and ask for clarifications from supervisor on the job requirement

communicate in local language

educate on precautions to be taken in order to avoid recurrence of problem

Decision Making

The user/individual on the job needs to know and understand how to:

follow standard operating procedures while making decisions

take approval from supervisor in case the decision has to be made for

exceptions.

Organizational Context

company’s policies on: incentives, delivery standards, and personnel

management

work flow involved in company’s process

importance of the individual’s role in the workflow

reporting structure

Work with superiors and colleagues

Knowledge

how to communicate effectively

how to build team coordination

Writing Skills

complete forms such as work orders, invoices, maintenance records

note problems on job sheet and details of work done

Reading Skills

read warnings, instructions and other text material on product labels,

components, etc.

read job sheets or work orders

read product and module serial numbers and interpret details such as make,

date, availability

Oral Communication (Listening and Speaking skills)

receive and ask for clarifications from supervisor on the job requirement

communicate in local language

educate on precautions to be taken in order to avoid recurrence of problem

Decision Making

follow standard operating procedures while making decisions

take approval from supervisor in case the decision has to be made for

exceptions

Plan and Organize

work with supervisor and co-workers to achieve smooth workflow

work with superiors and co-workers to share knowledge and learning

Customer Centricity

maintain personal grooming

be polite, patient and courteous under all circumstances with all types of

customers

decide on the spot on whether interaction of customer with superior is

necessary or not

maintain proper etiquette with customer during conversation

seek permission before entering customer’s premises

put customer at ease and generate customer’s confidence

Problem Solving

seek inputs at assess the problems

Critical Thinking

improve work processes

Understand potential sources of accidents

spot and report potential hazards on time

follow company policy and rules regarding hazardous materials

avoid accidents related to use of potentially dangerous chemicals, gases,

sharp tools and hazards from machines which involves exposure to possible

injuries such as cuts, bites, stings, minor burns, etc.

handle with care when using an electrical drill and sharp cutting objects

Use safety gear to avoid accidents

identify which safety gear must be used for a particular task

eye, respiratory and hearing protection as per company policy

use safety gear such as respirator, mask, skull caps, gloves, goggles, jacket,

etc., as prescribed for the job

Understand the safety procedures followed by the company

comply with standard health and safety procedure followed in the company

while handling an equipment and hazardous materials and tools or situations

identify and follow the evacuation procedure properly such as fire drills,

emergency evacuation procedures, first aid to self and others, etc., which

help in case of an emergency

Follow daily safety measure

take adequate safety measures while on work to prevent accidents

ensure zero accidents in work

avoid damage of components due to negligence in ESD procedures

ensure no loss for company due to safety negligence

ensure proper machine maintenance, work process achieving quality outputs

as per the company standard

Communicate to supervisor

improve process flow to reduce anticipated or repetitive hazards

report on mishandling of tools, machines or hazardous materials and on

electrical problems that could result in accident

escalate about any hazardous materials or things found in the premises

report about any breach of safety procedure in the company

follow electrostatic discharge (ESD) measures for electronic component safet

Customer Centricity

maintain personal grooming

be polite, patient and courteous under all circumstances with all types of

customers

decide on the spot on whether interaction of customer with superior is

necessary or not

maintain proper etiquette with customer during conversation

seek permission before entering customer’s premises

put customer at ease and generate customer’s confidence

Problem Solving

seek inputs at assess the problems

Critical Thinking

improve work processes