Auto-tester Capacitor(6 Month Diploma)

Auto-tester Capacitor

Auto-tester: The Auto-tester programs the auto testing machine for

segregating defective capacitors from passed ones.

Brief Job Description: The individual at work is responsible for testing the

capacitor using automated testing machine for electrical, tan-delta and

capacitance as per machine specifications.

Personal Attributes: The job requires the individual to have: attention to

details, and ability to work for long hours.

Test capacitor using auto tester

This unit/task covers the following:

Understand the work requirement

Set up the auto-test machine and run test

Undertake preventive maintenance of the machine

Achieve productivity and quality of standards

Performance Criteria

To be competent, the user/individual on the job must be able to:

collect the wound capacitor

record the number received and lot details

coordinate with supervisor to understand the day’s target

read job sheet to know the specifications for the lot received, work

instruction notes and work manuals

ensure capacitors match the purchase order

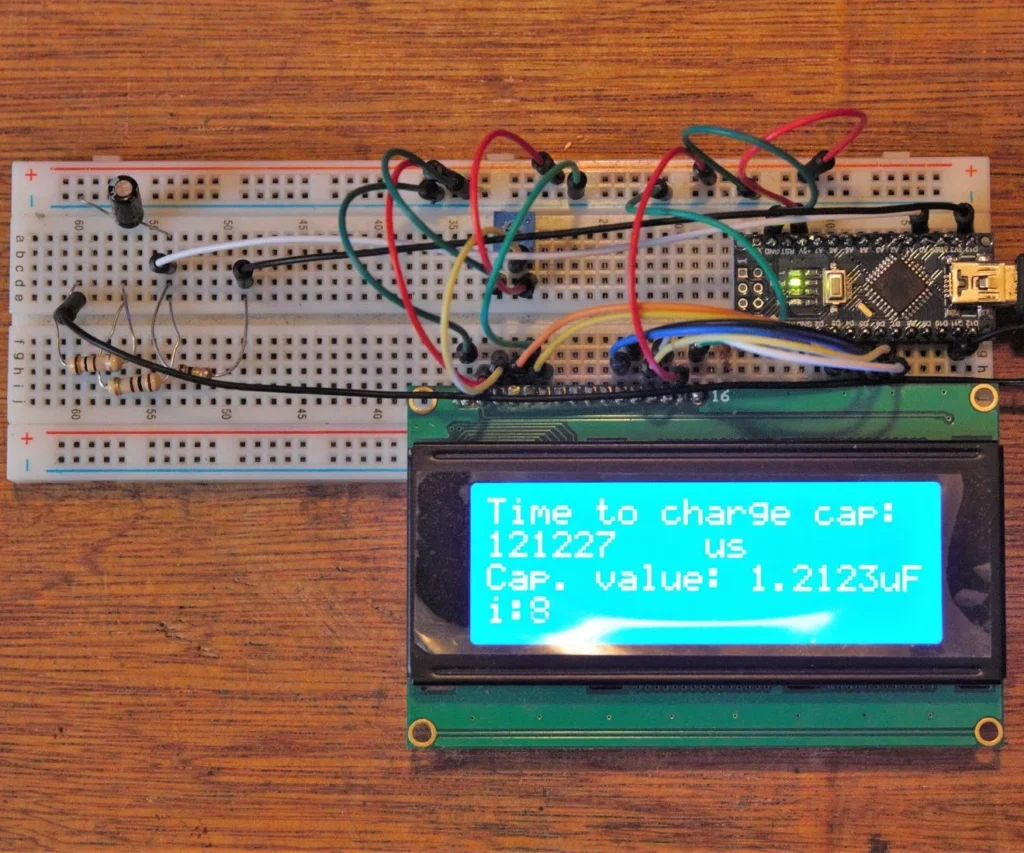

check setting of the auto tester, e.g., voltage and current

select program for the specific capacitor lot

load the film capacitor on the wheel

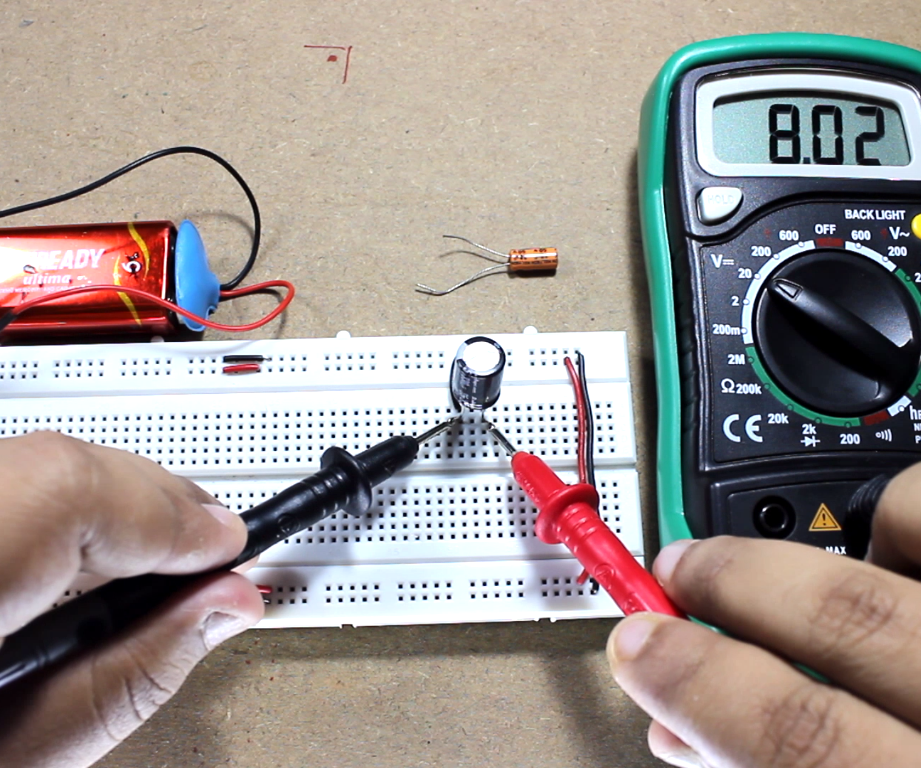

run the tests, e.g., electrical (short or open), tan-d, capacitance

segregate passed from failed capacitors

stack the tested products for further processing

record test status

compare test results to specifications against sample

mark the tested products based on acceptance or rejection

discuss test results to suggest recurring faults and corrective actions

ensure that auto-tester is cleaned periodically as per manufacturer’s

instructions

rectify and rework on malfunctioning equipment

achieve 100% target number of capacitors to be tested

ensure 100% quality guarantee

The individual on the job needs to know and understand:

Organizational Context

company’s policies on: incentives, delivery standards

work flow involved in production process of the company

importance of the individual’s role in the workflow

reporting structure

profile of clients

component stocking policy

safety and quality standards followed in the organization

Technical Knowledge

basic electronics and component identification

types of capacitors such as film capacitor, electrolytic capacitor, ceramic, etc.

and testing process for them

AC, DC, motor-capacitors, their construction and practical applications

concepts of capacitance, power factor, leakage, self-dissipation, thermal

stability, current/voltage specifications, temperature sensitivity, polarity, etc.

manufacturing process and frequently occurring faults during

test instruments, their functioning, controls and repairs, e.g., ohmmeter,

multi-meter, voltmeter, ammeter, capacitance meter, oscilloscope ,

frequency meter

how to use voltage source and specify settings in order to carry out dielectric

testing of capacitors

polarity of components

5S system (sorting, setting, standardising, shining, sustaining)

Qualifications Pack For Auto tester – Capacitor

Core skills or generic skills are a group of skills that are the key to learning

and working in today’s world. These skills are typically needed in any

work environment in today’s world. These skills are typically needed in

any work environment. In the context of the OS, these include

communication related skills that are applicable to most job roles.

Function

Function is an activity necessary for achieving the key purpose of the

sector, occupation, or an area of work, which can be carried out by a

person or a group of persons. Functions are identified through functional

analysis and form the basis of OS.

Occupational Standards

OS specify the standards of performance an individual must achieve

when carrying out a function in the workplace, together with the

knowledge and understanding they need to meet that standard

consistently. Occupational Standards are applicable both in the Indian

and global contexts.

Professional Skills

Reflective Thinking

The individual on the job needs to know and understand how:

to learn from past mistakes regarding use of hazardous machines, tools or

chemicals

Critical Thinking

how to spot danger

procedure to follow in the event of a fire or other hazard

Handling Safety Equipment

how to use safety materials such as gloves, etc.

how to use safety equipment such as fire extinguisher during fire accidents

Decision Making

importance of reporting potential sources of danger

appropriate actions to be taken in the event of an accident

procedure for disposing of hazardous materials, safely and following

environmental guidelines