Free Aerospace Design Assistant Mechanical course (6 months)

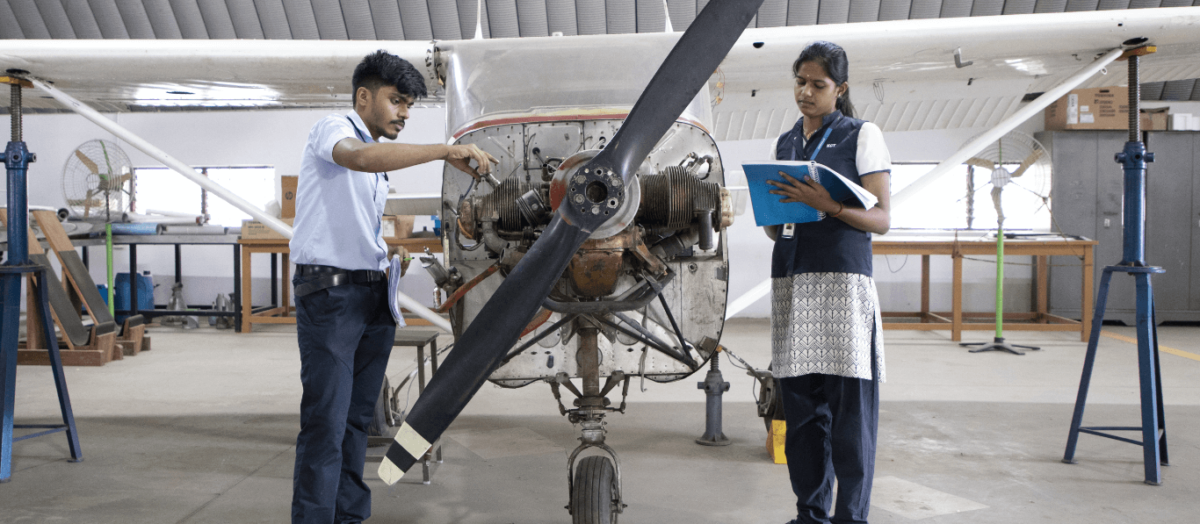

Aerospace Design Assistant Mechanical:

Brief Job Description: Aerospace Design Assistant- Mechanical is responsible for operating CAD (Computer Aided Design) machines and assist in design documentation and modification, design and development of mechanical components and systems.

Personal Attributes: The individual should have analytical ability, attention to detail and systematic thought process. He should have good communication and interpersonal skills and should be able to work as part of a team.

Documents for knowledge sharing:

Performance Criteria

PC1. establish with appropriate people the purpose, scope, formats and target

audience for the documents

PC2. access existing documents, language standards, templates and

documentation tools from your organization’s knowledge base

PC3. liaise with appropriate people to obtain and verify the information required

for the documents

PC4. confirm the content and structure of the documents with appropriate people

PC5. create documents using standard templates and agreed language standards

PC6. review documents with appropriate people and incorporate their inputs

PC7. submit documents for approval by appropriate people

PC8. publish documents in agreed formats

PC9. update your organization’s knowledge base with the documents

PC10. comply with your organization’s policies, procedures and guidelines when

creating documents for knowledge sharing

Knowledge and Understanding

Organisational Context

KA1. your organization’s policies, procedures and guidelines for creating documents for knowledge sharing

KA2. the purpose and scope of the work to be carried out and the importance of keeping within these boundaries

KA3. who to involve when developing documents and their roles and

responsibilities

KA4. intended audiences for documents

KA5. your organization’s knowledge base and how to access and update this

KA6. the importance of verifying information obtained for documents and how to

do this

KA7. the importance of reviewing documents with others

KA8. how to use feedback to improve documents

KA9. your organization’s processes and procedures for approving and publishing

documents

KA10. methods and techniques used when working with others

KA11. tools, templates and language standards available and how to use these

KA12. the work element for documents created

KA13. how to convert the work element into meaningful documents by proper

Technical Knowledge :-

KB1. the purpose and scope of the work to be carried out and the importance of

keeping within these boundaries

KB2. sources of information and reference materials for creating documents

KB3. different styles used in documents, including:

your organization’s house style

types and styles of documents

templates

KB4. different ways of structuring documents and how to select the best structure

for the agreed content

KB5. how to check and make corrections to documents for common editorial

problems and errors, including:

deviations

factual accuracies

linguistic mistakes

discrepancies

errors

ambiguities in content

Core Skills/ Generic Skills

| Writing Skills |

| You need to know and understand how to: SA1. complete accurate well written work with attention to detail SA2. communicate with others in writing |

| Reading Skills |

| You need to know and understand how to: SA3. follow guidelines, procedures, rules and service level agreements |

| Oral Communication (Listening and Speaking skills) |

| SA4. listen effectively and orally communicate information accurately SA5. ask for clarification and advice from others |

Professional Skills

| Decision Making |

| You need to know and understand how to: SB1. identify anomalies in data SB2. make a decision on a suitable course of action SB3. time management SB4. multi-tasking |

| Plan and Organise |

| You need to know and understand how to: SB5. plan and organize your work to achieve targets and deadlines SB6. manage your time effectively SB7. handle multiple tasks concurrently |

| Customer Centricity |

| You need to know and understand how to: SB8. check that your own and/or your peers’ work meets customer requirements SB9. work effectively in a customer facing environment SB10. build and maintain positive and effective relationships with customers. Problem Solving: SB11. seek clarification on problems from others SB12. apply problem-solving approaches in different situations SB13. refer anomalies to the line manager Analytical Skills You need to know and understand how to: SB14. analyze data and activities SB15. configure data and disseminate relevant information to others SB16. pass on relevant information to others Critical Thinking Skills You need to know and understand how to: SB17. provide opinions on work in a detailed and constructive way SB18. apply balanced judgments to different situations Attention to Detail You need to know and understand how to: SB19. check your work is complete and free from errors SB20. get your work checked by others Team Working You need to know and understand how to: SB21. work independently and collaboratively SB22. work effectively in a team environment SB23. contribute to the quality of team working Technical Skills SC1. use information technology effectively to input and/or extract data accurately SC2. identify and refer anomalies in data SC3. store and retrieve information SC4. keep data secure SC5. agree objectives and work requirements SC6. use coding standards SC7. keep up to date with changes, procedures and practices in your role Create and develop design documents: Performance Criteria Create, maintain design documents and provide information in standard format PC1. produce drawings, charts, graphs, wiring schematics, structure layouts and tables from specified instructions using standard drafting procedures to depict new components, assemblies, systems, or subsystems PC2. use computer-aided design or other graphic tools or drafting techniques to perform scaling, dimensioning, or line location PC3. calculate various dimensions or weights or volume using mathematical formulae from the graphical model developed PC4. work with engineers and developers to accurately depict the desired design characteristics PC5. recommend design modifications to improve quality of product and facilitate manufacturing operations PC6. assist plant employees in obtaining necessary drawings including blue prints of manufacturing drawings and information to implement improvements PC7. create as-built drawings and Field Walk Downs to ensure product conformity as per customer specification PC8. use current British, European, International and company standards to produce a drawing template for a range of paper sizes, and include the drawing title, scale used, date of drawing and other relevant information PC9. ensure clarity in the design processes documentations PC10. analyse strength for metal and composites PC11. obtain approvals from appropriate design authority PC12. conform to configuration management and change control procedures and policies PC13. assist/participate in design reviews, customer audits PC14. co-ordinate within the team and effectively communicate with all levels of the organisation Knowledge and Understanding Organisational Context KA1. organisation’s objective, vision, diversified segments, products etc. KA2. regulatory compliance with respect to modification and changes KA3. organisation’s requirement for IP protection KA4. hazard and risk management as defined by organisation KA5. compliance requirement for the roles and responsibility KA6. organisation’s safety and security requirements Technical Knowledge KB1. engineering drawings, limits, fits and tolerances, stack-up approach, principles, Interface control drawings and 3D freeform surfaces KB2. geometry creation and data management within 3D CAD software, or any software as recommended by the organisation KB3. calculations related to mechanics of material, electrical, aerodynamics etc. KB4. process for release of drawing and life-cycle management KB5. aerospace design and theory of flight Core Skills/ Generic Skills Writing Skills The user/individual on the job needs to know and understand how to: SA1. complete accurately, a well written report, in the English language Reading Skills The user/individual on the job needs to know and understand how to: SA2. read instructions/guidelines/procedures/rules Oral Communication (Listening and Speaking skills) The user/individual on the job needs to know and understand how to: SA3. listen to and orally communicate information with all concerned Professional Skills Decision Making The user/individual on the job needs to know and understand how to: SB1. make decisions on a suitable course of action or response if permitted by the authority matrix Plan and Organise The user/individual on the job needs to know and understand how to: SB2. monitor efficient functioning of all activities SB3. plan and organise work to achieve targets and deadlines Customer Centricity The user/individual on the job needs to know and understand how to: SB4. communicate with customers and other stakeholders in a courteous manner SB5. maintain cordial work relationship Problem Solving The user/individual on the job needs to know and understand how to: SB6. identify trends/common causes for errors and suggest possible solutions to the supervisor/management SB7. identify and correct errors Analytical Skills The user/individual on the job needs to know and understand how to: SB8. analyse best possible solutions (cost, time, effort, etc.) suited for operations Critical Thinking Skills The user/individual on the job needs to know and understand how to: SB9. concentrate on task at hand and complete it without errors SB10. apply balanced judgments to different situations  Work Effectively in a Team: Performance Criteria Support the work team PC1. display courteous and helpful behaviour at all times PC2. take opportunities to enhance the level of assistance offered to colleagues PC3. meet all reasonable requests for assistance within acceptable workplace timeframes PC4. complete allocated tasks as assigned PC5. seek assistance when difficulties arise PC6. use questioning techniques to clarify instructions or responsibilities, PC7. identify and d isplay a non-discriminatory attitude in all contacts with customers and other staff members Maintain personal presentation PC8. observe appropriate dress code and presentation as required by the workplace, job role and level of customer contact PC9. follow personal hygiene procedures according to organisational policy Develop effective work habits PC10. interpret, confirm and act on workplace information, instructions and procedures relevant to the particular task PC11. interpret, confirm and act on legal requirements with regards to anti- discrimination, sexual harassment and bullying PC12. ask questions to seek and clarify workplace information PC13. plan and organise daily work routine within the scope of the job role PC14. prioritise and complete tasks according to required timeframes PC15. identify work and personal priorities and achieve a balance between competing priorities Knowledge and Understanding Organisational Context KA1. policies and procedures relating to the job role KA2. the value system of the organisation KA3. employee rights and obligations KA4. the reporting hierarchy and escalation matrix Technical Knowledge KB1. ask questions to identify and confirm requirements KB2. follow routine instructions through clear and direct communication KB3. use language and concepts appropriate to cultural differences KB4. use and interpret non-verbal communication KB5. the scope of information or materials required within the parameters of the job role KB6. consequences of poor team participation on job outcomes KB7. work health and safety requirements Core Skills/ Generic Skills Writing Skills, On the job the individual needs to be able to: SA1. complete documentation accurately SA2. write simple reports when required Reading Skills On the job the individual needs to be able to: SA3. read information accurately SA4. read and interpret data sheets Oral Communication (Listening and Speaking skills) The user/individual on the job needs to know and understand how to: SA5. listen to and orally communicate information with all concerned Professional Skills Decision Making On the job the individual needs to be able to: SB1. make appropriate decisions regarding the responsibilities of the job role Plan and Organise The user/individual on the job needs to know and understand how to: SB2. monitor efficient functioning of all activities SB3. plan and organise work to achieve targets and deadlines Customer Centricity The user/individual on the job needs to know and understand how to: SB4. communicate with customers and other stakeholders in a courteous manner SB5. maintain effective work relationship Problem Solving The user/individual on the job needs to know and understand how to: SB6. identify trends/common causes for errors and suggest possible solutions to the supervisor / management SB7. identify and correct errors Analytical Thinking The user/individual on the job needs to know and understand how to: SB8. analyse best possible solutions (cost, time, effort, etc.) suited for operations Critical Thinking The user/individual on the job needs to know and understand how to: SB9. concentrate on task at hand and complete it without errors SB10. apply balanced judgments to different situations  Maintain organisational safety and information security Performance Criteria Comprehending the safety and information security procedures PC1. comply with your organisation’s IT policies and procedures for safety of data and information PC2. adhere to the organisation’s policies pertaining to accesses granted, usage, modification of any information or recording or destruction of information PC3. report any identified breaches of data or information in any form to the authority as described by the organisation PC4. report any theft of intellectual property according to the organisation policy PC5. record, control the document version and take appropriate approvals for documents, plans or drawings according to organisational hierarchy PC6. follow your organisation’s safety procedures at workplace and act promptly, calmly, and efficiently in case of disruption PC7. recommend improvement related to safety and security at the workplace PC8. comply to any health and safety requirements set by the organisation Knowledge and Understanding Organisational Context KA1. regulatory requirements and organisation’s procedures for health, safety and information security KA2. what is meant by an Intellectual property (IP), including the identification and prevention of theft at workplace KA3. how and when to maintain version and document control, post seeking approvals from the competent organisational authority KA4. the 5S principles (Seiri, Seiton, Seiso, Seiketsu, and Shitsuke) for efficient productivity and quality at workplace Technical Knowledge KB1. have IP management, including filing patents/copyrights/design registrations, documentation and control KB2. design standards, practices, procedure and methods followed by your organisation KB3. how to report breaches in safety and information security KB4. cyber security policy of your organisation KB5. procedures for evacuation of staff at workplace KB6. reporting procedures related to health, safety and security Core Skills/ Generic Skills Writing Skills You need to know and understand how to: SA1. complete accurate, well written work with attention to detail Reading Skills You need to know and understand how to: SA2. read instructions, guidelines, procedures, rules and service level agreements Oral Communication (Listening and Speaking skills) You need to know and understand how to: SA3. listen effectively and orally communicate information accurately Professional Skills Decision Making You need to know and understand how to: SB1. make a decision on a suitable course of action Plan and Organise You need to know and understand how to: SB2. plan and organize your work to meet health, safety and security requirements Customer Centricity You need to know and understand how to: SB3. build and maintain positive and effective relationships with colleagues and customers Problem Solving You need to know and understand how to: SB4. apply problem solving approaches in different situations Analytical Skills You need to know and understand how to: SB5. analyse data and activities Critical Thinking Skills You need to know and understand how to: SB6. apply balanced judgments to different situations Make or modify 2D mechanical engineering drawings using CAD system Performance Criteria Preparing for 2D mechanical engineering drawings PC1. use appropriate sources to obtain the technical information relevant to the drawing to be created Technical information relevant to the drawing to be created: drawing brief; specifications(overall dimensions, materials, special procedures for manufacturing); drawing change or modification request; regulations; existing drawings/desi gns, sketches, notes from meetings/discussions; standards reference documents (eg. limits and fits, tapping drill charts, contraction allowances) PC2. identify design features, as appropriate to the drawing being produced Design features: function, materials, clearance, operating environment, quality, aesthetics, interfaces, physical space; tolerances PC3. ensure that the data and information received is complete and correct PC4. establish the drawing requirements from the data and information received PC5. report and rectify incorrect and inconsistent information in job specification documents as per organisation procedures PC6. access and use the correct drawing software PC7. select drafting equipment appropriate to the drawing method chosen PC8. check that all the equipment is correctly connected and in a safe and usable working condition PC9. power up the equipment and activate the appropriate drawing software Performing set-up activities PC10. customize system variables, menus and drawing defaults to produce the drawing to the appropriate scale PC11. develop macros as per approved procedures PC12. set up and check that all peripheral devices are connected and correctly operating and interface with ERP if required is available Peripheral devices could be: keyboard, mouse, light pen, digitizer/tablet, scanner, printer, plotter, etc. PC13. set the drawing datum at a convenient point PC14. set up drawing parameters (eg. layers, line types, color, text styles) to company procedures or to suit the drawing produced Make or modify 2D Mechanical engineering drawings using CAD system PC15. interpret and produce mechanical drawings, using first angle orthographic projections, isometric/oblique projections, third angle orthographic projections, sectional views PC16. apply drafting principles to produce various types of drawings that are consistent with applicable standards and procedures for use in various engineering activities Types of drawings: detail drawings, sub-assembly drawings, general arrangement drawings, installation drawings, exploded views Standards and procedures: organizational guidelines and procedures, recognized compliance agency/body standards, directives or codes of practice, CAD software standards/protocols, national and/or International standards or directives, customer standards and requirements, health, safety and environmental requirements Engineering Activities: production activities (such as processing of materials, fabrication, finishing, assembly, joining); installation activities (such as commissioning/decommissioning, site preparation, equipment installation); operational activities (such as movement of materials, workplace layouts, work-flow diagrams), maintenance activities (such as planned preventative maintenance, part/sub-assembly exchange) PC17. create a drawing template to the required standards, which includes all necessary detail (eg.) using various drawing tools Drawing template details: layers of drawings, scale, paper size, color setup, line types, dimension system, title, drawing number, date, text styles Drawing Tools: straight lines, hatching and shading on drawings, adding dimensions and text to drawings, producing layers of drawings, symbols and abbreviations, hidden detail, curved/contour lines, angled lines, circles or ellipses; parts lists, geometrical and dimensional tolerance, insertion of standard components, elevation, plane view, side view, sectional views, detail views PC18. use appropriate terminologies and techniques to create drawings, in the required formats, that are sufficiently and clearly detailed PC19. use keyboard command and pull down menus available in common CAD systems PC20. use codes and other references that follow the required conventions PC21. draw temporary fasteners and rivets PC22. draw components details and assembly drawings PC23. draw piping layouts, gears and machine foundation or base PC24. draw working drawings of jigs and fixtures PC25. draw detailed drawings of dies, moulds and press tools PC26. dimension and label the drawing as per approved procedures PC27. create detailed views using various scales to meet job requirements PC28. ensure that drawings are checked and approved by the appropriate person PC29. produce hard copies of the finished drawings PC30. check that the drawing is correctly titled and referenced; sawing is correctly titled and referenced PC31. save the drawing to an appropriate storage medium (eg. hard drive, CD/DVD, external storage device) PC32. create a separate backup copy and place it in safe storage PC33. identify component parts list with part name, description of part, material specification or part number, quantities and other details to prepare bill of materials as per organizational guidelines PC34. deal promptly and effectively with problems within control and seek help and guidance from the relevant people if you have problems that they cannot resolve PC35. ensure that changes are completed as required by organizational procedures PC36. shut down the CAD system to a safe condition on completion of the drawing activities Knowledge and Understanding Organisational Context KA1. legislation, standards, policies, and procedures followed in the company relevant to own employment and performance conditions KA2. relevant health and safety requirements applicable in the work place KA3. importance of working in clean and safe environment KA4. own job role and responsibilities and sources for information pertaining to employment terms, entitlements, job role and responsibilities KA5. reporting structure, inter-dependent functions, lines and procedures in the work area KA6. relevant people and their responsibilities within the work area KA7. escalation matrix and procedures for reporting work and employment related issues KA8. documentation and related procedures applicable in the context of employment and work KA9. importance and purpose of documentation in context of employment and work Technical Knowledge KB1. organizational procedures and information systems for retrieving and storing drawing data KB2. system variables that can be customized KB3. procedures and need for customizing identified system variables KB4. applicable drafting standards/procedures KB5. procedures and need for customizing menus and system defaults KB6. procedures and need for developing macros KB7. appropriate projection for the drawing purpose KB8. reasons for selecting the chosen projection KB9. reasons for including auxiliary views in drawings KB10. procedures for producing component, layout and/or assembly drawings KB11. drawing specifications KB12. common symbols used in drawings KB13. how and where to obtain the relevant sources and methods for obtaining any required technical information relevant to the drawing KB14. methods and procedures used to minimize the chances of infecting a computer with a virus KB15. procedure to follow in case there are corruptions or virus attacks KB16. practices that make systems vulnerable to corruption and damage KB17. basic set-up and operation of the computer system, and the peripheral devices that are used (eg. light pen, digitizer and tablet, printer or plotter, scanner) KB18. how to access the specific computer drawing software to be used, and the use of software manuals and related documents to aid operation of the relevant drawing system KB19. basic principles of engineering manufacturing operations that are used to produce the drawn item Basic principles of engineering manufacturing operations: casting and forging; fabrication; machining methods; join ing processes; assembly and installation methods; limitations of the equipment/processes; kinematics principles relevant to manufacturing of machinery KB20. t ypes of drawings that may be produced by the software KB21. selection of standard components KB22. functionality of the component being drawn, and its interrelationship with other components and assemblies KB23. how to set up the viewing screen to show multiple views of the drawing to help with drawing creation KB24. standards and conventions that are used for the drawings KB25. how to set up the drawing template parameters KB26. application and use of drawing tools KB27. how to access, recognize and use a wide range of standard components and symbol libraries from the CAD equipment KB28. need for document control KB29. how to save and store drawings KB30. need to create backup copies, and to file them in a separate and safe location KB31. how to produce hard copies of the drawings, and the advantages and disadvantages of printers and plotters Core Skills/ Generic Skills Communication The user/individual on the job needs to know and understand how to: SA1. read and interpret information correctly from various job specification documents, manuals, health and safety instructions, memos, etc. applicable to the job in English and/or local language SA2. fill up appropriate technical forms, process charts, activity logs as per organizational format in English and/or local language SA3. convey and share technical information clearly using appropriate language SA4. check and clarify task-related information SA5. liaise with appropriate authorities using correct protocol SA6. communicate with people in respectful form and manner in line with organizational protocol Numerical and computational skills The user/individual on the job needs to know and understand how to: SA7. undertake numerical operations, and calculations/ formulae Numerical computations: addition, subtraction, multiplication, division, fractions and decimals, percentages and proportions, simple ratios and averages SA8. identify and draw various basic, compound and solid shapes as per dimensions given Basic shapes: square, rectangle, triangle, circle Compound shapes: involving squares, rectangles, triangles, circles, semi-circles, quadrants of a circle Solid shapes: cube, rectangular prism, cylinder SA9. use appropriate units and number systems to express degree of accuracy Units and number systems representing degree of accuracy: decimals places, significant figures, fractions as a decimal quantity SA10. interpret and express tolerance in terms of limits on dimensions SA11. calculation of the value of angles in a triangle Angles in a triangle: right-angled, isosceles, equilateral Learning The user/individual on the job needs to know and understand how to: SA12. participate in on-the-job and other learning, training and development interventions and assessments SA13. clarify task related information with appropriate personnel or technical adviser SA14. seek to improve and modify own work practices SA15. maintain current knowledge of application standards, legislation, codes of practice and product/process developments Computer Basics The user/individual on the job needs to know and understand how to: SA16. perform basic operations in a computer like switching it on/off, using the mouse and keyboard, accessing files, opening, closing, creating and deleting folders, etc. SA17. access and use word-processers and spreadsheets in a computer SA18. retrieve and enter data using standard system forms and templates SA19. receive and send emails using preset email accounts SA20. take printouts of documents Professional Skills Problem Solving The user/individual on the job needs to know and understand how to: SB1. identify problems with work planning, procedures, output and behavior and their implications SB2. prioritize and plan for problem solving SB3. communicate problems appropriately to others SB4. identify sources of information and support for problem solving SB5. seek assistance and support from other sources to solve problems SB6. identify effective resolution techniques SB7. select and apply resolution techniques SB8. seek evidence for problem resolution Plan and Organise The user/individual on the job needs to know and understand how to: SB9. plan, prioritize and sequence work operations as per job requirements SB10. organize and analyze information relevant to work SB11. basic concepts of shop-floor work productivity including waste reduction, efficient material usage and optimization of time Initiative and Enterprise The user/individual on the job needs to know and understand how to: SB12. undertake and express new ideas and initiatives to others SB13. modify work plan to overcome unforeseen difficulties or developments that occur as work progresses SB14. participate in improvement procedures including process, quality and internal/external customer/supplier relationships SB15. one’s competencies in new and different situations and contexts to achieve more Self-Management The user/individual on the job needs to know and understand how to: SB16. exercise restraint while expressing dissent and during conflict situations SB17. avoid and manage distractions to be disciplined at work SB18. manage own time for achieving better results Teamwork The user/individual on the job needs to know and understand how to: SB19. work in a team in order to achieve better results SB20. identify and clarify work roles within a team SB21. communicate and cooperate with others in the team for better results SB22. seek assistance from fellow team members Critical Thinking The user/individual on the job needs to know and understand how to: SB23. apply, analyze, and evaluate the information gathered from observation, experience, reasoning, or communication, as a guide to thought and actions Make or modify 3D mechanical engineering drawings using CAD system Performance Criteria Preparing for 3D mechanical engineering modelling using CAD system PC1. plan the modelling activities before starting them PC2. use appropriate sources to obtain the required information Required information: model brief/request, specifications , change order/modification request, regulations, manuals, sample component, calculations, previous models/designs, sketches, notes from meetings/discussions, standards reference documents (such as limits and fits, tapping drill charts), other available data PC3. access and use the correct modelling software and tools Modelling software and tools: solid modelling, wire frame modelling, surface modelling PC4. check that all the equipment is correctly connected and in a safe and usable working condition PC5. power up the equipment and activate the appropriate modelling tools PC6. set up the modelling environment and select a suitable template/folder PC7. set up and check that all peripheral devices are connected and correctly operating (such as keyboard, mouse, light pen, digitizer/tablet, scanner, printer, plotter) PC8. set the drawing datum at a convenient point to create a modelling template with title, file number, material, date PC9. establish coordinate system, orientation and views as per the job Creating and making changes to 3D mechanical engineering models using CAD system PC1 0. create entities in 3D space as per job requirement PC11. modify entities in 3D space as per job requirement PC12. create 3-D views on the screen by manip ulating drawing planes and inserting 3-D geometric shapes PC13. creating swept, extruded and revolved solids in 3-D space PC14. produce sectioned models (cutting planes and cross hatching) PC15. use pre-drawn library files and primitives to produce a 3-D model PC16. extracting mass and area properties from solid model PC17. identify and use key features of solid modelling software package to produce models Key features: extrude, extrude cut, solid model, mirror, revolve, wire frame, radius/chamfer, hide, rib, rectangular pattern, fillet, cut/remove, circular pattern, shell, development view, motion analysis, animation, defining material property, exploded views PC18. perform drawing for solid modelling PC19. extract physical properties as per job requirement, including volume, mass and centre of gravity PC20. take into account the following factors, as appropriate to the model being produced Factors: function, cost, physical space, quality, lifetime of the product, operating environment, manufacturing method, tolerances, interfaces, ergonomics, clearance, safety, materials, aesthetics, apply rendering techniques PC21. use pan, isometric and zoom CAD operations to highlight design areas in the modelling environment PC22. modify parts in the assembly environment using the following features Features: constrained parts and assemblies, straight lines, insertion of standard components, hidden detail, dimensions, symbols and abbreviations, hatching and shading, angular surfaces, curved surfaces, parts lists, text, circles or ellipses, material color, surface texture PC23. produce 3-D drawings incorporating section views with all necessary annotation PC24. produce a model for export to the following manufacturing systems Manufacturing systems: DNC (Direct Numerically controlled) /CNC(Computer Numerically controlled) machines; 3D printer; other specific system PC25. produce models which comply with organizational guidelines; statutory regulations and codes of practice; CAD software standards; national and international standards PC26. confirm that the model is as per job specifications and contains all relevant information PC27. use appropriate techniques to create models that are sufficiently and clearly detailed PC28. use codes and other references that follow the required conventions PC29. make sure that models are checked and approved by the appropriate person PC30. save the models in the appropriate file type and location PC31. produce hard copies of the finished models, with sufficient detail to allow production PC32. deal promptly and effectively with problems within your control, and seek help and guidance from the relevant people if you have problems that you cannot resolve PC33. shut down the CAD system to a safe condition on completion of the modelling activities Knowledge and Understanding Organisational Context KA1. specific health, safety and environmental requirements that apply to the product or process to be designed KA2. the limits of their own authority, and to whom they should report if they have problems that they cannot resolve KA3. importance of establishing and recording responsibilities KA4. organizational procedures and information systems for storing drawing data KA5. relevant sources and methods for obtaining any required technical information relevant to the model being produced (such as drawing briefs, specification sheets, request for changes or modifications to models; technical information such as limits and fits, contraction allowances, bearing selection, surface finish Technical Knowledge KB1. identification of the correct 3D drawing software package from the menu or windows environment; the various techniques that are available to access and use the CAD software (such as mouse, menu or tool bar, light pens, digitizers and tablets, printers or plotters, and scanners) KB2. how to access the specific computer modelling software to be used, and the use of the help file to aid efficient operation of the relevant drawing system KB3. documentation required for particular applications (such as design briefs, specification sheets, request for change orders KB4. types of drawings that may be produced by the modelling software KB5. how to set up the viewing screen to show multiple views of the component to help with drawing creation (to include isometric front and side elevations) KB6. national, international and organizational standards and conventions that are used for the models/drawings KB7. application and use of modelling tools (such as for straight lines, curves and circles; how to add dimensions and text to drawings) KB8. how to access, recognize and use a wide range of standard components and symbol libraries from the CAD equipment KB9. applications of different 3D modelling programs surface modelling solid modelling wire frame modelling KB10. how to produce models with sufficient information to allow them to be successfully exported to the manufacturing system used KB11. need for document control (such as ensuring that completed models are approved, labelled and stored on a suitable storage medium) KB12. need to create backup copies, and to file them in a separate and safe location, also filing and storing hard copies for use in production KB13. how to produce hard copies of the drawings, and the advantages and disadvantages of printers and plotters KB14. purpose for which the 3D model is to be developed KB15. appropriate coordinate system for the job KB16. reasons for selecting the chosen coordinate system KB17. orientation of the model with respect to the coordinate system KB18. number of views required to establish the model KB19. procedures for creating entities in 3D space KB20. entities that can be created/manipulated in 3D space KB21. procedures for manipulating entities in 3D space KB22. procedures for creating ruled and revolved surfaces in 3D KB23. applications of ruled and revolved surfaces KB24. procedures for modifying existing 3D models KB25. procedures for saving drawing files KB26. various formats in which drawing files can be saved KB27. reasons for using different formats when saving drawing files KB28. procedures for extracting data with respect to the physical properties of shapes created in 3D space KB29. physical properties of shapes created in 3D space that can be extracted from the drawing file KB30. erecting of exploded views KB31. creating own toolbox KB32. dynamic simulation of models creating intelligent models using parametric modelling KB33. producing composite models (composite regions and composite solids) KB34. producing sectioned models (cutting planes and cross hatching) KB35. using pre-drawn library files and primitives to produce a 3-D model KB37. applying rendering techniques to a 3D model (rendering types and preferences, render lighting techniques, and views and scenes) KB38. using various materials and surface finish options KB39. producing hard copies of 3-D solid models KB40. saving 3-D models in various file formats for retrieval into other CAD application software Core Skills/ Generic Skills Communication The user/individual on the job needs to know and understand how to: SA1. read and interpret information correctly from various job specification documents, manuals, health and safety instructions, memos, etc. applicable to the job in English and/or local language SA2. fill up appropriate technical forms, process charts, activity logs as per organizational format in English and/or local language SA3. convey and share technical information clearly using appropriate languag e SA4. check and clarify task-related information SA5. liaise with appropriate authorities using correct protocol SA6. communicate with people in respectf ul form and manner in line with organizational protocol SA7. listen to questions and concerns of the customer and provide resolution in a respectful manner as per organizational guidelines SA8. use basic office applications like spread sheet, word processor, presentations SA9. use ERP software and other organizational software specific to quality function SA10. use email to communicate within the organisation as per organisation guidelines SA11. be well dressed and groomed SA12. put forward ones point of view in a convincing manner Numerical and computational skills The user/individual on the job needs to know and understand how to: SA13. undertake numerical operations, and calculations/ formulae numerical computations: addition, subtraction, multiplication, division, fractions and decimals, percentages and proportions, simple ratios and averages SA14. identify and draw various basic, compound and solid shapes as per dimensions given Basic shapes: square, rectangle, triangle, circle Compound shapes: involving squares, rectangles, triangles, circles, semi-circles, quadrants of a circle Solid shapes: cube, rectangular prism, cylinder SA15. use appropriate units and number systems to express degree of accuracy Units and number systems representing degree of accuracy: decimals places, significant figures, fractions as a decimal quantity SA16. interpret and express tolerance in terms of limits on dimensions SA17. calculation of the value of angles in a triangle Angles in a triangle: right-angled, isosceles, equilateral Computer Basics The user/individual on the job needs to know and understand how to: SA18. perform basic operations in a computer like switching it on/off, using the mouse and keyboard, accessing files, opening, closing, creating and deleting folders, etc. SA19. access and use word-processers and spreadsheets in a computer SA20. retrieve and enter data using standard system forms and templates SA21. receive and send emails using preset email accounts SA22. take printouts of documents Learning The user/individual on the job needs to know and understand how to: SA23. maintain current knowledge of applicable standards, legislation, codes of practice and product/process developments SA24. participate in on-the-job and other learning, training and development interventions and assessment SA25. clarify task related information with appropriate personnel or technical adviser SA26. seek to improve and modify own work practices Professional Skills Problem Solving The user/individual on the job needs to know and understand how to: SB1. identify problems with work planning, procedures, output and behavior and their implications SB2. prioritize and plan for problem solving SB3. communicate problems appropriately to others SB4. identify sources of information and support for problem solving SB5. seek assistance and support from other sources to solve problems SB6. identify effective resolution techniques SB7. select and apply resolution techniques SB8. seek evidence for problem resolution SB9. inspect quality of own or other employee’s work SB10. analyze information according to enterprise and work requirements SB11. use diagnostic skills to identify and determine causes of faults, including interpretation of in-built fault indicators and error codes SB12. take decisions within if within own jurisdiction or take approval for case outside own jurisdiction Plan and Organise The user/individual on the job needs to know and understand how to: SB13. plan, prioritize and sequence work operations as per job requirements SB14. organize and analyze information relevant to work SB15. basic concepts of work productivity including waste reduction, efficient material usage and optimization of time Initiative and Enterprise The user/individual on the job needs to know and understand how to: SB16. work towards achieving better results for self, others and organisation by displaying initiative and enterprise SB17. undertake and express new ideas and initiatives to others SB18. modify work plan to overcome unforeseen difficulties or developments that occur as work progresses SB19. participate in improvement procedures including process, quality and internal/external customer/supplier relationships SB20. achieve more by applying one’s competencies in new and different situations and contexts to achieve more SB21. identify potential business opportunities for the company Self-Management The user/individual on the job needs to know and understand how to: SB22. work taking responsibility for own work outcomes SB23. adhere to work timings, dress code and other organizational policies SB24. work following laid down rules, procedures, instructions and policies SB25. conduct oneself express dissent during conflict situations while exercising restraint SB26. avoid and manage distractions to be disciplined at work SB27. work by time management for achieving better results Customer Centricity The user/individual on the job needs to know and understand how to: SB28. communicate with customers following organizational protocols and practices generating customer satisfaction and delight SB29. undertake clear and open communication with customers for trust building and clarifying and managing expectations of customers SB30. respond to customer expectation promptly and recognizing and communicating limits of one’s authority SB31. deal with customer feedback SB32. handle customer disgruntlement and dissatisfaction Teamwork The user/individual on the job needs to know and understand how to: SB33. work in a team in order to achieve better results SB34. identify and clarify work roles within a team SB35. communicate and cooperate with others in the team SB36. seek assistance from fellow team members SB37. co-ordinate across teams and personnel for getting work done Model Curriculum Aerospace Design Assistant Create documents for knowledge sharing establish with appropriate people the purpose, scope, formats and target audience for the documents access existing documents, language standards, templates and documentation tools from the organization’s knowledge base liaise with appropriate people to obtain and verify the information required for the documents confirm the content and structure of the documents with appropriate people create documents using standard templates and agreed language standards review documents with appropriate people and incorporate their inputs submit documents for approval by appropriate people publish documents in agreed formats update the organization’s knowledge base with the documents comply with the organization’s policies, procedures and guidelines when creating documents for knowledge sharing Create and develop design documents produce drawings, charts, graphs, wiring schematics, structure layouts and tables from specified instructions using standard drafting procedures to depict new components, assemblies, systems, or subsystems use computer-aided design or other graphic tools or drafting techniques to perform scaling, dimensioning, or line location calculate various dimensions or weights or volume using mathematical formulae from the graphical model developed work with engineers and developers to accurately depict the desired design characteristics recommend design modifications to improve quality of product and facilitate manufacturing operations assist plant employees in obtaini ng necessary drawings including blue prints of manufacturing drawings and information to implement improvements create as-built drawings and Field Walk Downs to ensure product conformity as per customer specification use current British, European, International and company standards to produce a drawing template for a range of paper sizes, and include the drawing title, scale used, date of drawing and other relevant information ensure clarity in the design processes documentations analyse strength for metal and composites obtain approvals from appropriate design authority conform to configuration management and change control procedures and policies assist/participate in design reviews, customer audits co-ordinate within the team and effectively communicate with all levels of the organisation Work Effectively in a Team display courteous and helpful behaviour at all times take opportunities to enhance the level of assistance offered to colleagues meet all reasonable requests for assistance within acceptable workplace timeframes complete allocated tasks as required seek assistance when difficulties arise use questioning techniques to clarify instructions or responsibilities identify and display a non -discriminatory attitude in all contacts with customers and other staff members observe appropriate dress code and presentation as required by the workplace, job role and level of customer contact follow personal hygiene procedures according to organisational policy and relevant legislation interpret, confirm and act on workplace information, instructions and procedures relevant to the particular task interpret, confirm and act on legal requirements in regard to anti- discrimination, sexual harassment and bullying ask questions to seek and clarify workplace information plan and organise daily work routine within the scope of the job role prioritise and complete tasks according to required timeframes identify work and personal priorities and achieve a balance between competing priorities Maintain organisational safety and information security comply with the organization’s IT policies and procedures for safety of data and information adhere to the organisation’s policies pertaining to accesses granted, usage, modification of any information or recording or destruction of information report any identified breaches of data or information in any form to the authority as described by the organization report any theft of intellectual property according to the organisation policy record, control the document version and take appropriate approvals for the documents, plans or drawings according to organisational hierarchy follow your organization’s safety procedures at workplace and act promptly, calmly, and efficiently in case of disruption recommend improvement related to safety and security at the workplace comply to any health and safety requirements set by an organisation Make or modify 2D mechanical engineering drawings using CAD system use appropriate sources to obtain the technical information relevant to the drawing to be created Technical information relevant to the drawing to be created: drawing brief; specifications(overall dimensions, materials, special procedures for manufacturing); drawing change or modification request; regulations; existing drawings/designs, sketches, notes from meetings/discussions; standards reference documents (e.g. limits and fits, tapping drill charts, contraction allowances) identify design features, as appropriate to the drawing being produced Design features: function, materials, clearance, operating environment, quality, aesthetics, interfaces, physical space; tolerances ensure that the data and information received is complete and correct establish the drawing requirements from the data and information received report and rectify incorrect and inconsistent information in job specification documents as per organisation procedures access and use the correct drawing software select drafting equipment appropriate to the drawing method chosen check that all the equipment is correctly connected and in a safe and usable working condition power up the equipment and activate the appropriate drawing software customize system variables, menus and drawing defaults to produce the drawing to the appropriate scale develop macros as per approved procedures set up and check that all peripheral devices are connected and correctly operating and interface with ERP if required is available set the drawing datum at a convenient point set up drawing parameters (e.g. layers, line types, color, text styles) to company procedures or to suit the drawing produced interpret and produce mechanical drawings, using first angle orthographic projections, isometric/oblique projections, third angle orthographic projections, sectional views apply drafting principles to produce various types of drawings that are consistent with applicable standards and procedures for use in various engineering activities detail drawings, sub-assembly drawings, general arrangement drawings, installation drawings, exploded views Standards and procedures: organizational guidelines and procedures, recognized compliance agency/body standards, directives or codes of practice, CAD software standards/protocols, national and/or International standards or directives, customer standards and requirements, health, safety and environmental requirements Engineering Activities: production activities (such as processing of materials, fabrication, finishing, assembly, joining); installation activities (such as commissioning/decommissioning, site preparation, equipment installation), operational activities (such as movement of materials, workplace layouts, work-flow diagrams), maintenance activities (such as planned preventative maintenance, part/sub-assembly exchange) create a drawing template to the required standards, which includes all necessary detail (e.g.) using various drawing tools use appropriate terminologies and techniques to create drawings, in the required formats, that are sufficiently and clearly detailed use keyboard command and pull down menus available in common CAD systems use codes and other references that follow the required conventions draw temporary fasteners and rivets draw components details and assembly drawings draw piping layouts, gears and machine foundation or bas draw working drawings of jigs and fixtures draw detailed drawings of dies, moulds and press tools dimension and label the drawing as per approved procedures create detailed views using various scales to meet job requirements ensure that drawings are checked and approved by the appropriate person produce hard copies of the finished drawings check that the drawing is correctly titled and referenced; sawing is save the drawing to an appropriate storage medium (e.g. hard drive, CD/DVD, external storage device) create a separate backup copy and place it in safe storage identify component parts list with part name, description of part, material specification or part number, quantities and other details to prepare bill of materials as per organizational guidelines deal promptly and effectively with problems within control and seek help and guidance from the relevant people if you have problems that they cannot resolve ensure that changes are completed as required by organizational procedures shut down the CAD system to a safe conditio n on completion of the drawing activities Make or modify 3D mechanical engineering models using CAD system plan the modellin g activities before starting them use appropriate sources to obtain the required information like, model brief/request, specifications, change order/modification request, regulations, manuals, sample component, calculations, previous models/designs, sketches, notes from meetings/discussions, standards reference documents (such as limits and fits, tapping drill charts), other available data access and use the correct modelling software and tools like, solid modelling, wire frame modelling, surface modelling check that all the equipment is correctly connected and in a safe and usable working condition power up the equipment and activate the appropriate modelling tools set up the modelling environment and select a suitable template/folder set up and check that all peripheral devices are connected and correctly operating (such as keyboard, mouse, light pen, digitizer/tablet, scanner, printer, plotter) set the drawing datum at a convenient point to create a modelling template with title, file number, material, date establish coordinate system, orientation and views as per the job create entities in 3D space as per job requirement modify entities in 3D space as per job requirement create 3-D views on the screen by manipulating drawing planes and inserting 3-D geometric shapes creating swept, extruded and revolved solids in 3-D space produce sectioned models (cutting planes and cross hatching) use pre-drawn library files and primitives to produce a 3-D model extracting mass and area properties from solid model identify and use key features of solid modelling software package to produce models with key features like extrude, extrude cut, solid model, mirror, revolve, wire frame, radius/chamfer, hide, rib, rectangular pattern, fillet, cut/remove, circular pattern, shell, development view, motion analysis, animation, defining material property, exploded views perform drawing for solid modelling extract physical properties as per job requirement, including volume, mass and Centre of gravity take into account the following factors, as appropriate to the model being produced Factors: function, cost, physical space, quality, lifetime of the product, operating environment, manufacturing method, tolerances, interfaces, ergonomics, clearance, safety, materials, aesthetics, apply rendering techniques use pan, isometric and zoom CAD operations to highlight design areas in the modelling environment modify parts in the assembly environment using the following features: constrained parts and assemblies, straight lines, insertion of standard components, hidden detail, dimensions, symbols and abbreviations, hatching and shading, angular surfaces, curved surfaces, parts lists, text, circles or ellipses, material color, surface texture produce 3-D drawings incorporating section views with all necessary annotation produce a model for export to the following manufacturing systems like, DNC (Direct Numerically controlled) /CNC(Computer Numerically controlled) machines; 3D printer; other specific system produce models which comply with organizational guidelines; statutory regulations and codes of practice; CAD software standards; national and international standards confirm that the model is as per job specifications and contains all relevant information use appropriate techniques to create models that are sufficiently and clearly detailed use codes and other references that follow the required conventions make sure that models are checked and approved by the appropriate person save the models in the appropriate file type and location produce hard copies of the finished models, with sufficient detail to allow production deal promptly and effectively with problems within your control, and seek help and guidance from the relevant people if you have problems that you cannot resolve shut down the CAD system to a safe condition on completion of the modelling activities Assist in developing electrical system co-ordinate with designers to understand the specifications, standards and methodology to produce drawings collect information on load, routing requirement, connector types, power terminals etc. from designer. co-ordinate and collect information from other engineering designers to understand the aerospace structural layout apply engineering concepts, processes and principles in developing the drawings develop circuit and wiring diagrams, block diagrams, schematics, electrical cabling/routing, installation, assembly of panels and sub-assemblies and system design/modification prepare drawings using AutoCAD, CATIA, CAD or Pro E software assist in preparation of Detailed Product Description (DPD), Design Specification Package (DSP), drawings, test order and reports minimise errors in the engineering drawing and suggest suitable changes use current British, European, International and company standards to produce a drawing template for a range of paper sizes, and include the drawing title, scale used, date of drawing and other relevant information obtain approvals from appropriate design authority timely interact with manufacturing team in case any clarifications required conform to configuration management and change control procedures and policies assist/participate in design reviews and customer audits co-ordinate within the team and effectively communicate with all levels of the organisation Guidelines for Assessment 1. Criteria for assessment for each Qualification Pack will be created by the Sector Skill Council. Each Performance Criteria (PC) will be assigned marks proportional to its importance in NOS. SSC will also lay down proportion of marks for Theory and Skills Practical for each PC. 2. The assessment for the theory part will be based on knowledge bank of questions created by the SSC. 3. Assessment will be conducted for all compulsory NOS, and where applicable, on the selected elective/option NOS/set of NOS. 4. Individual assessment agencies will create unique question papers for theory part for each candidate at each examination/training centre (as per assessment criteria below). 5. Individual assessment agencies will create unique evaluations for skill practical for every student at each examination/training centre based on this criterion. 6. To pass the Qualification Pack, every trainee should score a minimum of 70% of aggregate marks to successfully clear the assessment. 7. In case of unsuccessful completion, the trainee may seek reassessment on the Qualification Pack. |