Electronics Course

Verification Engineer ( 6 Month Diploma)

VLSI Design Engineer ( 6 Month Diploma )

Business Development Executive ( 6 Month Diploma )

Cutting, Crimping and Connector Assembly Operator(6 Month Diploma)

Silicone Painting Operator ( 6 Month Diploma )

Capping Operator ( 6 Month Diploma )

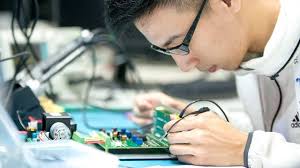

Manual Soldering Technician(6 Month Diploma)

Vacuum Plant Operator (6 Month Diploma)

Auto-tester Capacitor(6 Month Diploma)

Winding Operator (6 Month Diploma)