Free Plastic Moulding Shift In Charge Course (6Months)

Plastic Moulding Shift In Charge CLICK HERE

Brief Job Description

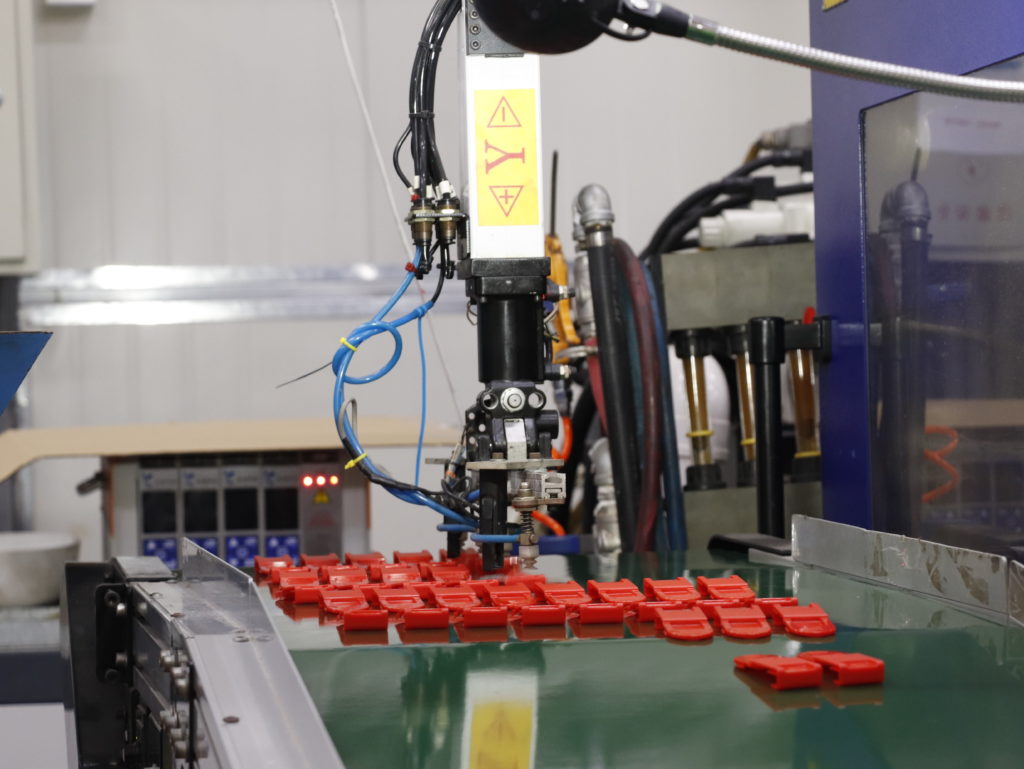

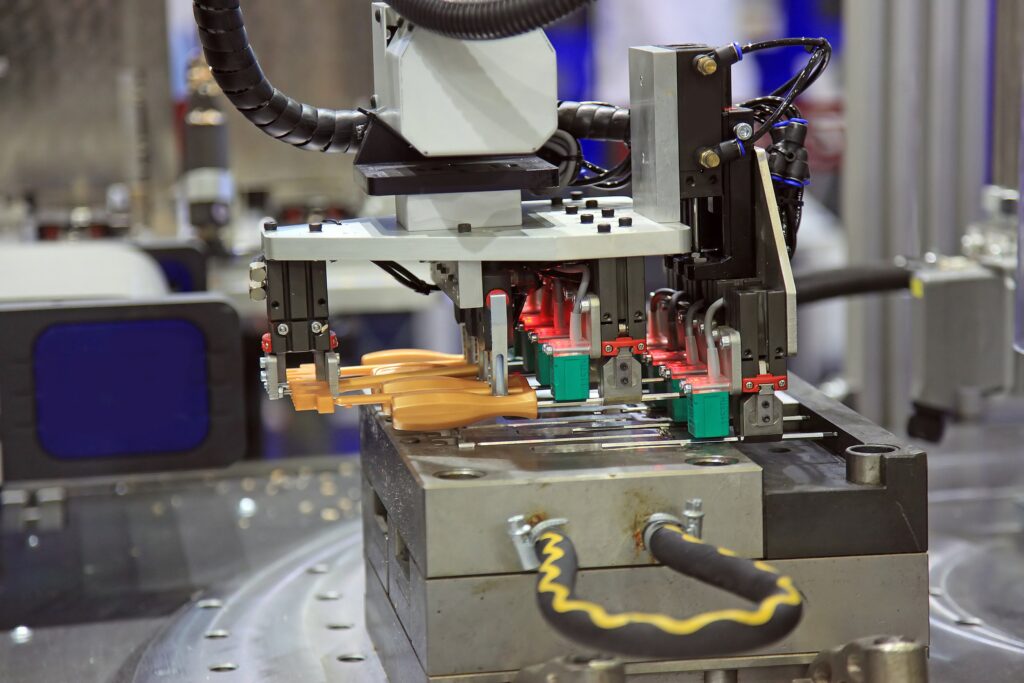

This role is responsible for managing PVC moulding and extrusion activities during the shift, maintaining process parameters, deploying manpower as per requirement, guiding operatives and technicians to complete the assigned task, maintaining a safe & healthy working environment on the shop floor and maintaining records related to production, rejections, material movement and manpower productivity for a line/shift. The role holder is also responsible to set the moulding machine parameters and the process flow during operations.

Personal Attributes

Technical knowledge of moulding and extrusion, reading, writing and communication skills, ability to plan and prioritize, quality consciousness, analytical thinking, sensitivity to problem solving, quick decision making, safety orientation, dexterity and high precision, ability to use internal ERP systems ( if existing), managing teams, grievance management, listening skills, ability to train team members.

Maintain a safe and healthy working environment:

Elements and Performance Criteria

Identify and report the risks identified

To be competent, the user/individual on the job must be able to:

PC1.. Identify activities which can cause potential injury through sharp objects, burns, fall, electricity, gas leakages, radiation, poisonous fumes, chemicals ,loud noise

PC2. Inform the concerned authorities about the potential risks identified in the processes, workplace area/ layout, materials used etc

PC3. Inform the concerned authorities about machine breakdowns, damages which can potentially harm man/ machine during operations

PC4. Create awareness amongst other by sharing information on the identified risks

Create and sustain a Safe, clean and environment friendly work place

To be competent, the user/individual on the job must be able to:

PC5.. Follow the instructions given on the equipment manual describing the operating process of the equipments

PC6.. Follow the Safety, Health and Environment related practices developed by the organization

PC7. Operate the machine using the recommended Personal Protective Equipments (PPE)

PC8. . Maintain a clean and safe working environment near the work place and ensure there is no spillage of chemicals, production waste, oil, solvents etc

PC9. Maintain high standards of personal hygiene at the work place

PC10. Ensure that the waste disposal is done in the designated area and manner as per organization SOP.

PC11. Inform appropriately the medical officer/ HR in case of self or an employees illness of contagious nature so that preventive actions can be planned for others

Knowledge and Understanding (KU)

The individual on the job needs to know and understand:

KU1. relevant standards, procedures and policies related to Health, Safety and Environment followed in the company

KU2. basic knowledge of Safety procedures( fire fighting, first aid) within the organization

KU3. knowledge of various types of PPEs and their usage

KU4. basic knowledge of risks/hazards associated with each occupation in the organization

KU5. how to safely operate various tools and machines and risksassociated with the tools/ equipment

KU6. knowledge of personal hygiene and how an individual an contribute towards creating a highly safe and clean working environment

Generic Skills (GS)

User/individual on the job needs to know how to:

GS1. write basic level notes and observations

GS2. read safety instructions put up across the plant premises

GS3. read safety precautions mentioned in equipment manuals and panels to understand the potential risks associated

GS4. effectively communicate information to team members

GS5. informemployees in the plant and concerned functions about events, incidents & potential risks observed related to Safety, Health and Environment.

GS6. question operator/ supervisor in order to understand the safety related issues

GS7. attentively listen with full attention and comprehend the information given by the speaker during safety drills and training programs

GS8. use common sense and make judgments during day to day basis

GS9. use reasoning skills to identify and resolve basic problems

GS10. use common sense and make judgments during day to day basis

GS11. use reasoning skills to identify and resolve basic problems

Understanding process requirements:

Elements and Performance Criteria

Understanding all the requisite processes in detail and ensuring implementation

To be competent, the user/individual on the job must be able to:

PC1. . display detailed understanding of all the requisite processes to be adopted for completing the work order through reading the process manuals/ work instructions/standard operating procedures for the production job

PC2.. ensure first level drafting of process manuals, work instructions, control plans, process flow charts to enable the team to easily understand and implement the process

PC3. . ensure proper display of work instructions, control plans and flow charts at the correct places on the shop floor to enable timely and proper view of the documents

PC4. . share knowledge of processes , inputs and outputs with the operators and in order to enhance their skill levels

PC5.. maintain work flow by monitoring steps of the processes, setting variables, observing control points and equipment

PC6. . monitor various process parameters on a regular basis and ensure compliance to agreed standards (e.g. ambient air quality, stack monitoring, water quality monitoring etc.)

PC7. . ensuring recording and reporting procedures and systems are in place

PC8. . facilitating corrections to malfunctions within process control points

PC9. . ensure that all the tools and measuring instruments used on the shop floor are inspected, tested and calibrated internally/ externally as per the schedule

PC10. . support the shop head/ process head in arranging for the requisite usage certificates for the tools and equipment as per the internal guidelines of the organization

PC11.. ensure 5s implementation in the production line by analysing possible areas of systems and process improvements and ensureimplementation of the recommended measures to address the gaps

PC12.. ensure successful implementation of the completed poka yoke and kaizen on the running line

PC13.. support the shop head/ process manager in conducting first level audit of the manufacturing process on the shop floor

Process Improvement

To be competent, the user/individual on the job must be able to:

PC14. . ensure optimum resource utilization and wastage reduction through process improvements, kaizens, TQM, Poka Yoke etc. in the shift

PC15. . provide inputs for analysis of breakdown trends and current maintenance process to identify areas for improvement to achieve cost savings and reduce breakdown timing

PC16.. identify areas of improvement in the existing processes/systems and take measures to adhere to the identified kaizen/ process improvement initiatives

PC17. . ensure inputs from the line operators are considered while designing for various poka yoke

, kaizen initiatives

PC18. . encourage team members/ supervisor/ operators to suggest quality improvement measures through suggestion schemes, evaluate feasibility of the ideas and discuss their implementation with seniors

PC19.. support in analysing internal & external rejection data, planning and ensuring implementation of the corrective measures

PC20. . ensure team has understanding of basic analytical tools like why why analysis, 7 QC tools, TQM principles to analyse various problems and design process improvement activities

PC21. . support the process engineering/ industrial engineering team in modifications of the process flow, process/ plant layout to improve the process TAT, operational ergonomics, work quality etc.

Implementation of various initiatives

To be competent, the user/individual on the job must be able to:

PC22.. take overall responsibility to ensure adherence to safety standards by all employees and establish zero accident practice in the section

PC23.. implement various business excellence techniques like kaizen, 5s initiatives, etc. to enhance productivity for the plant/ shift

Knowledge and Understanding (KU)

The individual on the job needs to know and understand:

KU1. relevant manufacturing standards and procedures followed in the company in detail

KU2. different types of products manufactured by the company

KU3. knowledge of functional processes like Procurement, Store management, inventory management, quality management and key contact points for query resolution

KU4. quality norms and standards prescribed in the Quality Manual by the organization for painting

KU5. 5S and Safety norms practiced in the organization

KU6. different types of manufacturing processes used

KU7. requirement of raw materials used in the process

KU8. about tools, jigs and fixtures , their usage and maintenance methods

KU9. how to operate the machine in both, automatic and manual mode

KU10. basic understanding of robotics, CNC operations, data acquisitions systems, automatic recording instruments

KU11. using engineering drawings, sketches, control plan and work instructions in the plant

KU12. usage of various measurement tools like VernierCalipers, Micrometres, rulers, scales, weighing machines etc

KU13. basic arithmetic and calculation methods

KU14. how to handle electrical equipment and circuits, rectifiers and control panel etc.

KU15. different types of defects which may arise due to improper manufacturing and the impact of the defect on product performance

KU16. metallurgical and chemical properties of material involved

KU17. how to measure the correct specifications of the output in the terms of thickness, hardness, durability, tightness, finesse etc.

KU18. . various problems solving tools like 7QC, Why Why Analysis, Brain storming etc.

KU19. key areas of power consumption/ steam consumption, compressed air consumption etc

KU20. various data entry tools and formats used in the organization

KU21. ability to visualize the final product output and hence decide on the key steps and parameters to be followed

KU22. usage of various business correspondence tools like Email, MS Office tools ( Word, Excel, Power Point) etc.

KU23. about the various hazards related to various chemicals if used in the processes, the hazards involved in the process operations and usage of PPEs

Generic Skills (GS)

User/individual on the job needs to know how to:

GS1. create first level process manuals, Control Plans, Work Instructions in an manner that the operators can easily understand the process requirements and process steps

GS2. create small notes/ work documents/ diagrams for supervisors ,operators and helpers to help them understand the process

GS3. use emails and other business correspondence methods ( internal memos, circular etc. ) for communicating with other team members/ vendors/ suppliers etc.

GS4. read equipment manuals and process documents given by the equipment supplier to understand the equipment and processes better

GS5. discuss task lists, schedules, and work-loads with the operative team members

GS6. effectively explain supervisors, operators and helpers about equipment operations, process steps and other operational requirements

GS7. answer the queries raised by the operative team as well as intercompany departments

GS8. effectively communicate with the operators and helpers and make them aware of work expectations, targets, policies, processes etc.

GS9. attentively listen with full attention the queries and grievances raised by the operative team and comprehend the information given by the speaker

GS10. communicate effectively to the team members

GS11. identify conflicts in the team and try to resolve them at the earliest

GS12. interact and engage with the team members on a day to day basis

GS13. counsel and coach the operators and help them resolve issues

GS14. timely highlight to the management about any good work/ achievement by the operators and helper

GS15. break the problem into smaller issues and tasks to arrive at a solution

GS16. understand inter process relationship and establish relationship between various parts of the problem

GS17. leverage experience to find effective solutions to problems

GS18. use basic analytical tools to arrive at solutions

GS19. plan, organize and prioritize the work order and jobs received from the production manager

GS20. manage the schedule plan for the operators and helpers on the line/shift

GS21. validate all process/ equipment manuals so that the final process selected is correct

GS22. organize information, tools, manuals etc. on the shop floor so that sorting becomes easy

GS23. reorganize resources on the line/ shift in case of change of plans

GS24. use common sense and make judgments during day to day basis

GS25. use reasoning skills to identify and resolve problems

GS26. use intuition to detect any potential problems which could arise during operations

GS27. critically analyse solutions/ recommendations shared by operatives and supervisors for implementation

GS28. accept additional responsibility for self and the team

GS29. encourage self and other to take greater responsibilities

GS30. ensure that the work allocated to the team is completed as per timelines and quality norms

GS31. identify obstacles and bottlenecks in the process and on own find basic level solutions for removing these obstacles

GS32. motivate and provide support for the team on the shop floor

GS33. encourage collaboration between team members

GS34. resolve team issues and grievances to manage conflicts within the team

GS35. create an environment of approachability, trust and openness within the team

GS36. ensure role clarity for all operators and helpers on the line/ shift

GS37. escalate any team related issues to the concerned person at the right time

GS38. identify defective parts in the manufacturing line by comparing manufactured pieces with the work standard

GS39. link the defect observed with the overall impact on the performance of the component/ automobile

GS40. support and contribute in monitoring and delivering high quality output from self and others

GS41. train team members on maintaining quality standards set by the organization

GS42. use previous experience in resolving problems and taking decisions

GS43. make timely and independent decisions on the line/ shift within the boundaries of the delegation matrix of the organization

GS44. familiarise with leading practices available in the market

GS45. think independently on new approaches to manufacturing process, material management, data management and team management

GS46. represent any new ideas/ approaches on process improvement and productivity improvement to the seniors in the team

Manage the production related operations of the shift/line on a day to day basis:

Elements and Performance Criteria

Manpower Management

To be competent, the user/individual on the job must be able to:

PC1.. undertake effective shift planning based on manpower allocation and shift handling of place right manpower on the right workstation in coordination with production in-charge to achieve production targets

PC2.. support the shop head/ process head in finalizing the shift rosters for the week and month based on the production plan available

Material Management

To be competent, the user/individual on the job must be able to:

PC3.. send inventory requirements to stores and purchase department and follow up with stores and purchase to ensure timely receipt of material (spares, consumables)

PC4.. ensure that the incoming raw material quality is inspected and meets the production requirement

PC5. . ensure that the material and work piece movement on the shop floor conforms to the TAT time prescribed in the SOP/ work plans so that production targets are met for the line/ shift

Supervise Production Operations

To be competent, the user/individual on the job must be able to:

PC6. . ensure that the production plan shared by the ppc team is fulfilled during the shift/ across lines

PC7. . coordinate with various functions like material management, stores, paint shop, assembly line, quality, safety, production planning etc. to ensure communication of required information and resolution of queries

PC8.. responsible for end of line inspection under supervision

PC9.. ensure that the operators and helpers have the required tools and equipment at the start of the process

PC10.. identify & implement action steps to reduce losses and wastages during shift operation and ensure minimum rejection of components

PC11. . observe and note the consumption of energy, fuel, steam on the production line and utilize these inputs for optimization of various factors of production

PC12. . support the maintenance team in finalizing the preventive maintenance schedule for the shop

PC13.. ensure that the operator and helper are using the required personal protective equipment like goggles, masks, gloves and other ppes at the time of conducting the painting operation

Conformance to Product and Process Quality

To be competent, the user/individual on the job must be able to:

PC14.. conduct random incoming quality inspection of material and provide the relevant feedback on the same to the store

PC15.. conduct quality inspection of the process parameters, lab parameters and wip products and provide necessary feedback to the line leaders

PC16.. conduct quality inspection of the first sample/batch to ensure that the quality of the product produced meet customer requirements

PC17.. conduct inspection and analysis of the defects observed in the process and products

Data Collation and Analysis

To be competent, the user/individual on the job must be able to:

PC18.. prepare daily and monthly production mis reports to match actual performance vis–vis the targets and report the same to production in-chart

PC19.. verify the production and material movement related data entries in the system ( manual/ erp) for the shift and ensure correctness of the data

PC20.. ensure compilation of data of breakdown maintenance and reporting the same to the maintenance team

PC21.. collaborate with the maintenance team in conducting detailed breakdown analysis to understand problems, look out for process/ machine modifications and resolve the issues

PC22.. conduct random sampling of the process parameters, finished goods and WIP products and provide necessary feedback to the line leaders

PC23.. collaborate with the quality management and inspection team in conducting detailed analysis to resolve issues

PC24.. collaborate with various supervisors to capture process data points as mentioned in the internal operating guidelines for data analytics

PC25.. support the shop head/ process head in analysing the various data points related to production, maintenance, manpower deployment, material management, costs etc.

PC26.. support the shop head/ process head in creating various analytical presentations required for process/ shop/ plant review

Knowledge and Understanding (KU)

The individual on the job needs to know and understand:

KU1. relevant manufacturing standards and procedures followed in the company in detail

KU2. different types of products manufactured by the company

KU3. knowledge of functional processes like Procurement, Store management, inventory management, quality management and key contact points for query resolution

KU4. quality norms and standards prescribed in the Quality Manual by the organization for painting

KU5. 5S and Safety norms practiced in the organization

KU6. different types of manufacturing processes

KU7. requirement of raw materials used in the process

KU8. about tools, jigs and fixtures , their usage and maintenance

KU9. how to operate both in automatic and manual mode

KU10. basic understanding of robotics, CNC operations, data acquisitions systems, automatic recording instruments

KU11. different types of defects which may arise due to improper manufacturing

KU12. basic Arithmetic and calculation methods

KU13. ability to visualize the final product output and hence decide on the key steps to be followe

KU14. about handling of electrical equipment and circuits, rectifiers and control panel etc

KU15. metallurgical and chemical properties of the material under usage

KU16. how to measure the correct specifications of the output in the terms of thickness, hardness, durability, tightness etc

KU17. how to visualize the final product output and hence decide on the parameters of temperature, pressure, current and voltage

KU18. various problems solving tools like 7QC, Why Why Analysis, Brain storming

KU19. usage of various business correspondence tools like Email, MS Office tools ( Word, Excel, Power Point) etc.

KU20. about the various hazards related to various chemicals if used in the processes, the hazards involved in the process operations and usage of PPEs

Generic Skills (GS)

User/individual on the job needs to know how to:

GS1. create first level process manuals, Control Plans, Work Instructions in an manner that the operators can easily understand the process requirements and process steps

GS2. create small notes/ work documents/ diagrams for supervisors ,operators and helpers to help them understand the process

GS3. use emails and other business correspondence methods ( internal memos, circular etc. ) for communicating with other team members/ vendors/ suppliers etc.

GS4. read equipment manuals and process documents given by the equipment supplier to understand the equipment and processes better

GS5. discuss task lists, schedules, and work-loads with the operative team members

GS6. effectively explain supervisors, operators and helpers about equipment operations, process steps and other operational requirements

GS7. answer the queries raised by the operative team as well as intercompany departments

GS8. effectively communicate with the operators and helpers and make them aware of work expectations, targets, policies, processes etc.

GS9. attentively listen with full attention the queries and grievances raised by the operative team and comprehend the information given by the speaker

GS10. communicate effectively to the team members

GS11. identify conflicts in the team and try to resolve them at the earliest

GS12. interact and engage with the team members on a day to day basis

GS13. counsel and coach the operators and help them resolve issues

GS14. timely highlight to the management about any good work/ achievement by the operators and helpers

GS15. identify problems occurring on the shop floor

GS16. break the problem into smaller issues and tasks to arrive at a solution

GS17. understand inter process relationship and establish relationship between various parts of the problem

GS18. leverage experience and technical expertise to find effective solutions to problems

GS19. use basic analytical tools to arrive at solutions

GS20. collaborate with cross functional teams to resolve problems

GS21. plan, organize and prioritize the work order and jobs received from the production manager

GS22. manage the schedule plan for the operators and helpers on the line/shift

GS23. validate all process/ equipment manuals so that the final process selected is correct

GS24. organize information, tools, manuals etc. on the shop floor so that sorting becomes easy

GS25. reorganize resources on the line/ shift in case of change of plans

GS26. use common sense and make judgments during day to day basis

GS27. use reasoning skills to identify and resolve problems

GS28. use intuition to detect any potential problems which could arise during operations

GS29. critically analyse solutions/ recommendations shared by operatives and supervisors for implementation

GS30. accept additional responsibility for self and the team

GS31. encourage self and other to take greater responsibilities

GS32. ensure that the work allocated to the team is completed as per timelines and quality norms

GS33. identify obstacles and bottlenecks in the process and on own find basic level solutions for removing these obstacles

GS34. motivate and provide support for the team on the shop floor

GS35. encourage collaboration between team members

GS36. resolve team issues and grievances to manage conflicts within the team

GS37. create an environment of approachability, trust and openness within the team

GS38. ensure role clarity for all operators and helpers on the line/ shift

GS39. escalate any team related issues to the concerned person at the right time

GS40. identify defective parts in the manufacturing line by comparing

GS41. manufactured pieces with the work standard

GS42. link the defect observed with the overall impact on the performance of the component/ automobile

GS43. support and contribute in monitoring and delivering high quality output from self and others

GS44. train team members on maintaining quality standards set by the organization

GS45. use previous experience in resolving problems and taking decisions

GS46. make timely and independent decisions on the line/ shift within the boundaries of the delegation matrix of the organization

GS47. familiarise with leading practices available in the market

GS48. think independently on new approaches to manufacturing process, material management, data management and team management

GS49. represent any new ideas/ approaches on process improvement and productivity improvement to the seniors in the team

Managing the team on the line/shift on a day to day basis:

Elements and Performance Criteria

Engaging the shop floor work force through employee communication and employee engagement

To be competent, the user/individual on the job must be able to:

PC1. . ensure operators and helpers on the production line/ shift are aware of the job expectations on a daily basis

PC2. . ensure that the operators are aware of the production targets and the timelines required to process a work order as finalized in the production plan

PC3.. involve operators and helpers for the daily floor meeting/ morning meetings/ staff meetings to communicate information intended for them

PC4. . ensure communication to line operators/ helpers on any changes in policies/ processes by the organization through required verbal/ written mechanisms

PC5. . ensure participation of employees in various engagement initiatives organized at the plant and other place by the organization

PC6. . involve operators and helpers in Quality Circles, TQM & kaizen meets, brainstorming sessions, safety drills etc. to increase their involvement in manufacturing operations

PC7. . ensure availability of tea, snacks, drinking water and basic hygiene facilities at the shop floor for the operative workforce.

PC8.. escalate issues to concerned staff in case of any issue related to operative deployment and engagement

PC9. . ensure employees at the shop floor are motivated and their concerns are resolved

Finalizing manpower deployment

To be competent, the user/individual on the job must be able to:

PC10. . finalize along with the process manager, the shift planning and manpower deployment for the shift/ line as per the proposed production plan

PC11. . support the process manager in creating week wise shift rosters for the shift/ line manpower and ensure rotation of manpower as per the organizational norms and guidelines

PC12. . maintain the information on leaves/ IN Out time keeping and shift/ line overtime for the operatives and helpers and share the information with the concerned as and when required

PC13.. identify skilled manpower for the process and ensure periodic up – dation of Skill Matrix/ skill chart for the shift/ line/ process area

PC14.. ensure identification and deployment of right skilled people at the right places on the line/ process area

Employee Performance Measurement and Employee Development

To be competent, the user/individual on the job must be able to:

PC15. . ensure that all the operative manpower is aware of the production targets, production plan and daily productivity targets

PC16. . track the daily performance of the operators and helpers during the shift and note the achievement levels in a manual register/ online it enabled system

PC17.. provide feedback to the operators and helper in case of any process deviation observed

PC18.. provide feedback to managers pertaining to performance appraisals of operators and helpers

PC19.. ensure that the operatives are trained and are aware of the processes which need to be followed on the shop floor during the production process

PC20. . support the manager and the training team in training of entry level operators and helpers in the plant

PC21. . share knowledge of processes , inputs and outputs with the operators to enhance their skill levels

PC22. . other than technical trainings, support the team by delivering trainings related to quality and safety for the operators and helpers

PC23. . drive a culture of creativity and innovation in the team by given the team members opportunity to think out of box and express their thoughts

Grievance Management for Operators and Helpers

To be competent, the user/individual on the job must be able to:

PC24. . in case the operating staff has any queries, ensure that the queries are resolved either by self or escalated to the concerned person

PC25. . listen to issues related to workmen problems/ work men grievances/ complaints/ personal problems etc. for the operators and helpers

PC26.. resolve issues which are under the purview of the supervisor and escalate the ones which need higher intervention to the concerned team

Knowledge and Understanding (KU)

The individual on the job needs to know and understand:

KU1. relevant HR Policies and Processes followed by the organization

KU2. different types of products manufactured by the company

KU3. knowledge of functional processes like Procurement, Store management, inventory management, quality management and key contact points for query resolution

KU4. 5S and Safety norms practiced in the organization

KU5. different types of manufacturing processes

KU6. various grievance management tools available in the organization

KU7. various problems solving tools like 7QC, Why Why Analysis, Brain storming

KU8. different types of communication channels practiced by the organization

KU9. the method of noting observations, maintaining records and sharing them with the concerned in the required format

KU10. knowledge of shift roster norms and guidelines

KU11. how and when to measure performance of the operators

KU12. how to share feedback with team members

Generic Skills (GS)

User/individual on the job needs to know how to:

GS1. document information from the manuals, discussion notes, process charts etc.

GS2. create small notes/ work documents/ diagrams for operators and helpers to help them understand the process

GS3. use emails and other business correspondence methods ( internal memos, circular etc. ) for communicating with other team members/ vendors/ suppliers etc

GS4. read internal information memos send by internal customers ( other functions within the organization)

GS5. discuss task lists, schedules, and work-loads with the operative team members

GS6. answer the queries raised by the operative team as well as intercompany departments

GS7. effectively communicate with the operators and helpers and make them aware of work expectations, targets, policies, processes etc.

GS8. attentively listen with full attention the queries and grievances raised by the operative team and comprehend the information given by the speaker

GS9. identify the strengths and weaknesses of the subordinate team members ( operators and helpers)

GS10. provide constructive and genuine feedback

GS11. motivate the team to take independently responsibilities in their work areas

GS12. provide training to the operators and helpers for technical and behavioural areas

GS13. communicate effectively to the team members

GS14. identify conflicts in the team and try to resolve them at the earliest

GS15. interact and engage with the team members on a day to day basis

GS16. counsel and coach the operators and help them resolve issues

GS17. timely highlight to the management about any good work/ achievement by the operators and helpers

GS18. display empathy for the problems faced by the team and act on the concerns

GS19. break the problem into smaller issues and tasks to arrive at a solution

GS20. understand inter process relationship and establish relationship between various parts of the problem

GS21. leverage experience to find effective solutions to problems

GS22. use basic analytical tools to arrive at solutions

GS23. collaborate with cross functional teams to resolve problems

GS24. use common sense and make judgments during day to day basis

GS25. use reasoning skills to identify and resolve problems

GS26. use intuition to detect any potential problems which could arise during operations

GS27. critically analyse solutions/ recommendations shared by operatives and supervisors for implementation

GS28. accept additional responsibility for self and the team

GS29. encourage self and other to take greater responsibilities

GS30. ensure that the work allocated to the team is completed as per timelines and quality norms

GS31. identify obstacles and bottlenecks in the process and on own find basic level solutions for removing these obstacles

GS32. motivate and provide support for the team on the shop floor

GS33. encourage collaboration between team members

GS34. resolve team issues and grievances to manage conflicts within the team

GS35. create an environment of approachability, trust and openness within the team

GS36. ensure role clarity for all operators and helpers on the line/ shift

GS37. escalate any team related issues to the concerned person at the right time

GS38. use previous experience in resolving problems and taking decisions

GS39. make timely and independent decisions on the line/ shift within the boundaries of the delegation matrix of the organization

Assessment Guidelines

- Criteria for assessment for each Qualification Pack will be created by the Sector Skill Council. Each Element/ Performance Criteria (PC) will be assigned marks proportional to its importance in NOS. SSC will also lay down proportion of marks for Theory and Skills Practical for each Element/ PC.

- The assessment for the theory part will be based on knowledge bank of questions created by the SSC.

- Assessment will be conducted for all compulsory NOS, and where applicable, on the selected elective/option NOS/set of NOS.

- Individual assessment agencies will create unique question papers for theory part for each candidate at each examination/training center (as per assessment criteria below).

- Individual assessment agencies will create unique evaluations for skill practical for every student at each examination/ training center based on these criteria.

- To pass the Qualification Pack assessment, every trainee should score the Recommended Pass % aggregate for the QP.

- In case of unsuccessful completion, the trainee may seek reassessment on the Qualification Pack.