Container Freight Station (CFS) and Inland Container Depot (ICD) Supervisor (1 years diploma)

Container Freight Station (CFS) and Inland Container Depot (ICD) Supervisor click here

Brief Job Description: The individual allocates resources for cargo handling and

container movement, plans and supervises repair and maintenance of

containers, while overseeing operations and general cleanliness within a CFS or

ICD.

Qualifications Pack for CFS and ICD supervisor

Option

Option 1: Yard and Cargo Handling

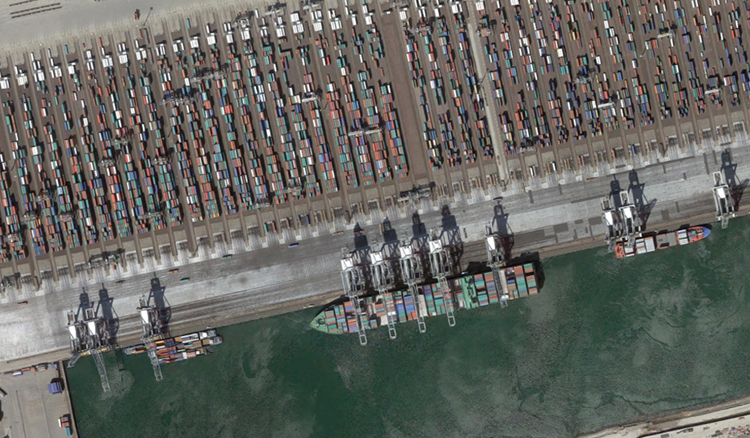

The unit is about supervising cargo handling and storage operations in the port

terminal, ICD or CFS

Personal Attributes:

The job holder should plan and budget for activities. S/he should have

digital/computer skills and mathematical aptitude to estimate yard space

requirement, and quantity estimation. S/he should have English and Vernacular

language proficiency, demonstrable in spoken, written and oral communication

Description

Core Skills/Generic

Skills

Core Skills or Generic Skills are a group of skills that are key to learning and

working in today’s world. These skills are typically needed in any work

environment. In the context of the NOS, these include communication related

skills that are applicable to most job roles.

Function

Function is an activity necessary for achieving the key purpose of the sector,

occupation, or area of work, which can be carried out by a person or a group

of persons. Functions are identified through functional analysis and form the

basis of NOS.

Job role Job role defines a unique set of functions that together form a unique

employment opportunity in an organization.

Knowledge and

Understanding

Knowledge and Understanding are statements which together specify the

technical, generic, professional and organizational specific knowledge that an

individual needs in order to perform to the required standard.

National Occupational

Standards (NOS) NOS are Occupational Standards which apply uniquely in the Indian context

Electives

Electives are NOS/set of NOS that are identified by the sector as contributive

to specialization in a job role. There may be multiple electives within a QP for

each specialized job role. Trainees must select atleast one elective for the

successful completion of a QP with Electives

Options

Options are NOS/set of NOS that are identified by the sector as additional

skills. there may be multiple options within a QP. It is not mandatory to select

any of the options to complete a QP with Options.

Unit Code Unit code is a unique identifier for an Occupational Standard, which is

denoted by an ‘N’

Unit Title Unit title gives a clear overall statement about what the incumbent should be

able to do.

Occupation Occupation is a set of job roles, which perform similar/related set of functions

in an industry.

Organizational Context

Organizational Context includes the way the organization is structured and

how it operates, including the extent of operative knowledge managers have

of their relevant areas of responsibility.

Performance Criteria Performance Criteria are statements that together specify the standard of

performance required when carrying out a task.

Qualifications

Pack(QP)

Qualifications Pack comprises the set of NOS, together with the educational,

training and other criteria required to perform a job role. A Qualifications

Pack is assigned a unique qualification pack code.

Qualifications Pack

Code

Qualifications Pack Code is a unique reference code that identifies a

qualifications pack.

Scope Scope is the set of statements specifying the range of variables that an

individual may have to deal with in carrying out the function which have a

critical impact on the quality of performance required.

Sector

Sector is a conglomeration of different business operations having similar

businesses and interests. It may also be defined as a distinct subset of the

economy whose components share similar characteristics and interests.

Sub-Sector Sub-sector is derived from a further breakdown based on the characteristics

and interests of its components.

Sub-functions Sub-functions are sub-activities essential to fulfil the achieving the objectives

of the function.

Technical Knowledge Technical Knowledge is the specific knowledge needed to accomplish specific

designated responsibilities.

Description

CFS Container Freight Station

DG Directorate General

ERP Enterprise Resource Planning

EXIM Export Import

FCL Full Container Load

GPS Global Positioning System

HAZCHEM Hazardous Chemicals

HR Human Resources

ICD Inland Container Depots

IMDG International Maritime Dangerous Goods

LCL Less than Container Load

MHE Material Handling Equipment

MIS Management Information Systems

NSQF National Skills Qualifications Framework

OH&S Occupational Health and Safety

OS Occupational Standards

OSHA Occupational Safety and Health Administration

PPE Personal Protective Equipment

QP Qualifications Pack

RFID Radio-Frequency Identification

SOP Standard Operating Procedure

VHF Very High Frequency

Allocate resources and streamline operations at yard

Description This unit is about allocating manpower and equipment for execution of work;

supervision and streamlining operations at a port terminal, ICD or CFS

Scope This unit/task covers the following:

• Prepare daily work plan and allocate resources

• Monitor daily operations

• Yard Inspection

• Resolve escalated issues

Range: Stationery, Radio-Frequency Identification (RFID) scanner, bar code scanner,

plastic bags, markers, Personal Protective Equipment (PPEs), Enterprise Resource

Planning (ERP), computer, printers, Global Positioning System (GPS) tracker,

Material Handling Equipment (MHEs), etc.

Performance Criteria(PC) w.r.t. the scope

Element Performance Criteria

Prepare daily work

plan and allocate

resources

To be competent, the user/ individual must be able to:

PC1. obtain details of vessel docking plans, cargo and container movement plans,

etc.

PC2. develop daily work plan factoring in priority cases, time bound

requirements, special handling requirements, etc.

PC3. get the work plan approved from the yard manager or Container Freight

Station (CFS)/ Inland Container Depot (ICD) manager and allocate tasks to

workers and associates

PC4. budget and allocate the requisite MHE for different tasks at hand

Monitor daily

operations

To be competent, the user/individual on the job must be able to:

PC5. inspect yard for markings/demarcation, storage and cleanliness, as per

safety norms

PC6. monitor cargo loading, unloading and movement operations

PC7. engage resources in alternate operation when there is a delay of planned

operations

PC8. allocate additional and ad-hoc manpower and equipment during exigency

PC9. escalate issues regarding MHE operations, transporter delays, vessel delays,

accidents, damages, etc. to manager

PC10. provide corrective and preventive action plans based on accident and

damage reports

PC11. liaise with port officials, customs officials and external stakeholders

Yard inspection To be competent, the user/ individual must be able to:

PC12. conduct periodic inspection of the yard for cleanliness, usage of PPEs and

adherence to Standard Operating Procedures (SOP) and regulations

PC13. ensure cargo bays are clearly marked and segregated, containers and cargo

are stored as per prescribed norms

PC14. check for parking and positioning of equipment as per SOP

PC15. ensure all necessary precautions for storage of hazardous cargo are

complied with and emergency services are available

PC16. submit inspection report highlighting any deviation from SOP

Resolve escalated

issues

To be competent, the user/ individual must be able to:

PC17. review escalated issues and identify root cause for providing corrective

action

PC18. provide technical guidance to the team for execution

PC19. escalate the issues to manager when external or additional help is required

PC20. coordinate with other departments, transporters, freight operators, port

authorities, shipping companies and others to resolve escalations if required

Knowledge and understanding (K)

A. Organizational

context (Knowledge of

the company /

organization

and its

processes)

The individual on the job needs to know and understand:

KA1. organizational procedures

KA2. documentation and reporting as per organization’s mandate

KA3. security procedures to be followed

KA4. escalation matrix for reporting identified problems

KA5. risk and impact of not following defined procedures/work instructions

KA6. coding system followed to label cargo

KA7. IT system and ERP system of the organization

B. Technical

knowledge

The individual on the job needs to know and understand:

KB1. yard operations and its technicalities

KB2. different type of cranes and MHEs – their capacities, constraints and usage

KB3. use of rope, flags and other manual equipment

KB4. vessel layout and loading and unloading activities

KB5. different type of vessels, cargo, container sizes and their handling

KB6. handling of hazardous and non-hazardous cargo – International Maritime

Dangerous Goods (IMDG) code

KB7. stuffing and de-stuffing norms with respect to different cargo and its special

characteristics

KB8. handling of hazardous and non-hazardous cargo – – IMDG code

KB9. special characteristics and handling requirements of shipments, if any

Skills (S)

A. Core skills/

generic skills

Reading skills

The user/individual on the job needs to know how to read:

SA1. written instructions

SA2. shiping manifest, Bill of lading shipping bills and related documents

SA3. ERP and computer generated reports

Allocate resources and streamline operations at port, ICD and CFS

SA4. cargo stowage plans and vessel plans

SA5. SOPs and safety regulation manuals

Writing skills

The user/individual on the job needs to know how to write:

SA6. work-orders and instructions

SA7. checklist of activities, delays, undelivered items, contacts, etc

SA8. daily reports

Oral communication (listening and speaking skills)

The user/individual on the job needs to know how to:

SA9. communicate with customers, fireght operators, transporters, shipping

companies, other supervisors and port authorities

SA10. communicate with cargo equipment operators and ground staff over VHF

radio

SA11. guide cargo handlers for smooth operations

B. Professional

skills

Decision making

The user/individual on the job needs to know how to:

SB1. decide on required workforce and equipment for performing a particular

task

SB2. assess the environmental condition and type of cargo to assess if it is safe

for operations

SB3. resolve a problem quickly internally

SB4. prioritise shipments

SB5. decide on deployment of alternate resources when required

Plan and organize

The user/individual on the job needs to know how to:

SB6. plan and estimate the co-ordination required for resolving a querry.

SB7. maintain punctuality

SB8. respond to the client in a timely manner

SB9. prioritize and execute tasks based on client requirements

SB10. make work plans and resource allocation plans

SB11. check on execution of work plans

SB12. be a team player and achieve joint goals

Customer centricity

The user/individual on the job needs to know how to:

SB13. adhere to the customer timelines

SB14. address the urgency regarding shipments and activities

Problem solving

The user/individual on the job needs to know how to:

SB15. make adjustment to working requirements for difficult weathers and

hazardous goods

SB16. identify trends/common causes for delays, damages, etc.

SB17. co-ordinate and handle major issues with different departments

SB18. identify bottlenecks and operational problems and suggest remedial action

Analytical thinking

The user/individual on the job needs to know how to:

SB19. assess the resource requirement for a particular task at hand

SB20. assess and prepare for backup resources in case of delays

SB21. plan for cargo movement so that the resources and stroage space is

optimally utilised

Critical thinking

The user/individual on the job needs to know and understand how to:

SB22. resolve issues in a qucik and cost effective manner

SB23. develop work plans factoring in external factors

SB24. check that all security measures and safety protocals are followed at all

times

Extract and analyse shipment information from IT systems

Description This unit is about reading shipment tracking ERPs, extracting information and

analysing the same

Scope This unit/task covers the following:

• Feed information into the ERP

• Track position of consignments and containers globally

• Document and report

Range: Stationery, Standard Operating Procedures (SOP), Radio-Frequency

Identification (RFID) scanner, bar code scanner, markers, ERP, computer, display

board, printer, etc.

Performance Criteria(PC) w.r.t. the scope

Element Performance Criteria

Feed information

into ERP

To be competent, the user/ individual must be able to:

PC1. obtain details of all containers moving in and out the Container Freight

Station (CFS) including container number, cargo content, destination, shipper

and vessel details, date of servicing, etc.

PC2. cross verify container status based on physical inspection report and yard

utilization report

PC3. correct the information in the shipment tracking ERP

Track position of

consignments and

containers globally

To be competent, the user/ individual must be able to:

PC4. track position of container in the ERP by feeding the Container index number

PC5. extract information regarding present location, shipper details, cargo content,

estimated date of arrival at destination, etc.

PC6. estimate equipment and workforce requirement considering the type of

cargo, stuffing/destuffing/packing requirement based on location and route

Document and report To be competent, the user/ individual must be able to:

PC7. prepare detailed documentation and present the analysis to the CFS or Inland

Container Depots (ICD) manager

PC8. highlight any accidents, issues in tracking, etc.

PC9. suggest corrective action in case of container packing mistakes, sealing errors,

that has led to damage or accidents

Knowledge and understanding (K)

A. Organizational

context

(Knowledge of the

company /

organization and

its processes)

The individual on the job needs to know and understand:

KA1. organizational procedures

KA2. documentation and reporting as per organization’s mandate

KA3. security procedures to be followed

KA4. escalation matrix for reporting identified problems

KA5. risk and impact of not following defined procedures/work instructions

KA6. coding system followed to label cargo

KA7. IT system and ERP system of the organization

B. Technical

knowledge

The individual on the job needs to know and understand:

KB1. basics of operations in a port terminal, ICD and CFS

KB2. use of various cargo handling equipment

KB3. vessel layout and loading and unloading activities

KB4. procedures of tank cleaning, cargo movement

KB5. requirements regarding handling of cargo

KB6. different type of vessels and cargo and container sizes

KB7. different type of cranes and Material Handling Equipment (MHEs) – their

capacities, constraints and usage

KB8. handling of hazardous and non-hazardous cargo – – International Maritime

Dangerous Goods (IMDG) code

KB9. marking of material and people movement areas

KB10. stuffing and de-stuffing norms with respect to different cargo

KB11. special characteristics and handling requirements of shipments, if any

KB12. different container tracking ERPs and their operation

KB13. location of different destinations on the map and the globe

Skills (S)

C. Core skills/

generic skills

Reading skills generic skills

The user/individual on the job needs to know how to read:

SA1. written instructions

SA2. shiping manifest, Bill of lading shipping bills and related documents

SA3. ERP and computer generated reports

SA4. cargo stowage plans and vessel plans

SA5. SOPs and safety regulation manuals

Writing skills

The user/individual on the job needs to know how to write:

SA6. work-orders and instructions

SA7. checklist of activities, delays, undelivered items, contacts, etc

SA8. daily reports

Oral communication (listening and speaking skills)

The user/individual on the job needs to know how to:

SA9. communicate with customers, freight operators, transporters, shipping

companies, other supervisors and port authorities

SA10. communicate with cargo equipment operators and ground staff over VHF

radio

SA11. guide cargo handlers for smooth operations

D. Professional skills Decision making

The user/individual on the job needs to know how to:

SB1. decide if a particular shipment has been correctly tagged in the ERP

SB2. decide the ageing and decide for container repairs and servicing

Plan and organize

The user/individual on the job needs to know how to:

SB3. plan and estimate the co-ordination required for resolving a querry.

SB4. maintain punctuality

SB5. respond to the client in a timely manner

SB6. prioritize and execute tasks based on client requirements

SB7. make work plans and resource allocation plans

SB8. make checks on execution of work plans

SB9. be a team player and achieve joint goals

Customer centricity

The user/individual on the job needs to know how to:

SB10. adhere to the customer timelines

SB11. address the urgency regarding shipments and activities

Problem solving

The user/individual on the job needs to know how to:

SB12. make adjustment to effectively track missing containers

SB13. identify trends/common causes for delays, damages, etc.

SB14. co-ordinate and handle major issues with different departments

SB15. identify bottlenecks and operational problems and suggest remedial action

Analytical thinking

The user/individual on the job needs to know how to:

SB16. assess if the availble resources fit for the type and volume of cargo handled as

per ERP

SB17. identify commonly carried cargo and routes and destination

SB18. plan for container repair and servicing

Critical thinking

The user/individual on the job needs to know and understand how to:

SB19. resolve issues in a qucik and cost effective manner

SB20. develop inferences based on analysis and data of ERPs

SB21. check that all security measures and safety protocals are followed at all times

for all its containers across the globe

Plan and check for optimal utilization of yard space

Description This unit is about planning to ensure optimal utilization of yard space within the port,

CFS or ICD and supervision of timely cargo movement

Scope This unit/task covers the following:

• Review yard space utilization

• Assess storage requirement for incoming cargo

• Coordinate for timely movement of cargo

• Inspect yard

Range: Stationery, Standard Operating Procedures (SOP), Radio-Frequency

Identification (RFID) scanner, bar code scanner, markers, Enterprise Resource

Planning (ERP), computer, display board, printer, etc.

Performance Criteria(PC) w.r.t. the scope

Element Performance Criteria

Review yard space

utilization

To be competent, the user/ individual must be able to:

PC1. review the yard and bay space utilization by cargo and container and assess

current available storage capacity

PC2. review ageing of different containers and dry bulk cargo that has come onto

the port / CFS and are due for movement to the CFS/ client respectively

PC3. conduct meeting with yard staff and check for reasons for over or

underutilization of yard space, reasons for delay in cargo movement and take

corrective action

PC4. escalate issues to terminal manager if required

Assess storage

requirement of

incoming cargo

To be competent, the user/ individual must be able to:

PC5. obtain details of vessel berthing plan and cargo loading and unloading plan

into the CFS, ICD

PC6. check if the yard has appropriate yard capacity to handle the incoming cargo

PC7. make adjustment by shipping out aged cargo onto the CFS, shipper or

exporting the cargo onto the vessel (port in case of CFS)

PC8. identify and finalise yards and bays for storage of incoming cargo considering

the various demarcations and precautions to be taken, particularly for

hazardous and dry bulk cargo

PC9. prepare cargo storage plans based on vessel berthing plan and get it

approved from the terminal manager

PC10. communicate the cargo storage plan to the cargo handlers, lifting supervisors

and vessel planners

Coordinate for timely

movement of cargo

To be competent, the user/ individual must be able to:

PC11. coordinate with vessels, transporters and shippers for movement cargo to

Plan and ensure optimal utilization of yard space

and from the CFS/ICD

PC12. oversee movement of cargo from port terminal, CFS via rail and road lines

and export via vessels

PC13. review cargo movement documentation and ensure correctness

PC14. prepare report on cargo storage plans, their adherence, cargo movement

plans and cargo ageing

Inspect yard To be competent, the user/ individual must be able to:

PC15. check for cleanliness, adequate use of Personal Protective Equipment (PPEs),

regulations and norms for workforce are clearly followed

PC16. ensure that cargo bays are clearly marked and segregated, containers and

cargo are stored as per prescribed norms

PC17. inspect that equipment are parked are right positions

PC18. confirm that all necessary precautions for storage of hazardous cargo is in

place including emergency services

PC19. prepare inspection report highlighting any anomalies or changes, as required

Knowledge and understanding (K)

A. Organizational

context (Knowledge

of the

company /

organization

and its

processes)

The individual on the job needs to know and understand:

KA1. organizational procedures

KA2. documentation and reporting as per organization’s mandate

KA3. security procedures to be followed

KA4. escalation matrix for reporting identified problems

KA5. risk and impact of not following defined procedures/work instructions

KA6. coding system followed to label cargo

KA7. IT system and ERP system of the organization

B. Technical

knowledge

The individual on the job needs to know and understand:

KB1. basics of operations in a port terminal, ICD and CFS

KB2. use of various cargo handling equipment

KB3. use of rope , flags and other manual equipment

KB4. vessel layout and loading and unloading activities

KB5. procedures of tank cleaning, cargo movement

KB6. requirements regarding handling of cargo

KB7. different type of vessels and cargo and container sizes

KB8. different type of cranes and MHEs – their capacities, constraints and usage

KB9. handling of hazardous and non-hazardous cargo – International Maritime

Dangerous Goods (IMDG) code

KB10. marking of material and people movement areas

KB11. stuffing and de-stuffing norms with respect to different cargo

KB12. special characteristics and handling requirements of shipments, if any

Skills (S)

C. Core skills/ Reading skills generic skills

The user/individual on the job needs to know how to read:

SA1. written instructions

SA2. shiping manifest, Bill of lading shipping bills and related documents

SA3. ERP and computer generated reports

SA4. cargo stowage plans and vessel plans

SA5. SOPs and safety regulation manuals

Writing skills

The user/individual on the job needs to know how to write:

SA6. work-orders and instructions

SA7. checklist of activities, delays, undelivered items, contacts, etc

SA8. daily reports

Oral communication (listening and speaking skills)

The user/individual on the job needs to know how to:

SA9. communicate with customers, freight operators, transporters, shipping

companies, other supervisors and port authorities

SA10. communicate with cargo equipment operators and ground staff over VHF

radio

SA11. guide cargo handlers for smooth operations

D. Professional

skills

Decision making

The user/individual on the job needs to know how to:

SB1. decide on required workforce and equipment for performing a particular task

SB2. assess the environmental condition and type of cargo to assess if it is safe for

operations

SB3. resolve a problem quickly internally

SB4. prioritise shipments

SB5. decide on deployment of alternate resources when required

Plan and organize

The user/individual on the job needs to know how to:

SB6. plan and estimate the co-ordination required for resolving a querry.

SB7. maintain punctuality

SB8. respond to the client in a timely manner

SB9. prioritize and execute tasks based on client requirements

SB10. make work plans and resource allocation plans

SB11. make checks on execution of work plans

SB12. be a team player and achieve joint goals

Customer centricity

The user/individual on the job needs to know how to:

SB13. adhere to the customer timelines

SB14. address the urgency regarding shipments and activities

Problem solving

The user/individual on the job needs to know how to:

SB15. make adjustment to working requirements for difficult weathers and

hazardous goods

SB16. identify trends/common causes for delays, damages, etc.

SB17. co-ordinate and handle major issues with different departments

SB18. identify bottlenecks and operational problems and suggest remedial action

Analytical thinking

The user/individual on the job needs to know how to:

SB19. assess the resource requirement for a particular task at hand

SB20. assess and prepare for backup resources in case of delays

SB21. plan for cargo movement so that the resources and stroage space is optimally

utilised

Critical thinking

The user/individual on the job needs to know and understand how to:

SB22. resolve issues in a qucik and cost effective manner

SB23. develop work plans factoring in external factors

SB24. check that all security measures and safety protocals are followed at all times

Plan and coordinate for optimal utilization of available containers

Description The unit is about and planning and coordinating for utilization of available containers

and their stuffing and cargo containerisation

Scope This unit/task covers the following:

• Identify and use available containers

• Allocate resources for container stuffing and de-stuffing

• Allocate resources for container handling

• Review gate movement of containers and reporting

Range: Stationery, Standard Operating Procedures (SOP), Personal Protective

Equipment (PPE), Material Handling Equipment (MHEs), Radio-Frequency

Identification (RFID) scanner, bar code scanner, markers, Enterprise Resource

Planning (ERP), computer, display board, printer, etc.

Performance Criteria(PC) w.r.t. the scope

Element Performance Criteria

Identify and use

available containers

To be competent, the user/ individual must be able to:

PC1. track status of containers in the ERP and identify containers that are empty or

returning from servicing or repairs, and containers that are carrying Less than

Container Load (LCL) load

PC2. check with shipper the requirement regarding the type of cargo and if Full

Container Load (FCL) or LCL is required and recommend solution with

available container

PC3. check that necessary precaution and segregation of type of cargo has been

considered while allocating LCL containers

PC4. coordinate with client and finalise the timelines for container loading and

movement

Allocate resources for

container stuffing

and de-stuffing

To be competent, the user/ individual must be able to:

PC5. obtain the weekly container movement plan and prepare the daily stuffing

and de-stuffing plan

PC6. budget and allocate resources for stuffing, de-stuffing

PC7. conduct morning meeting with staff and workers to communicate the daily

plan and allocate the tasks

PC8. coordinate with the shipper or transporter to ensure if the cargo is available

for stuffing

PC9. oversee that container cargo handling operations are done with all

precautions and as per SOP to minimise errors and damages

Allocate resources for

container handling

To be competent, the user/ individual must be able to:

PC10. allocate resources and work orders for storage of stuffed/ de-stuffed

containers within the yard

PC11. coordinate with the equipment handlers regarding daily task for container

movement within the yard

PC12. coordinate with shipper and transporter for movement of stuffed/ de-stuffed

containers outside the Container Freight Station/ Inland Container Depots

(CFS/ ICD)

Review gate

movement of

containers and

reporting

To be competent, the user/ individual must be able to:

PC13. check gate logs and entries for movement of containers into and outside of

the CFS/ ICD

PC14. prepare documentation of daily container movement and cargo handling

activities

PC15. update the ERP regarding the container details, location and status

PC16. provide daily end of the day report to manager regarding status of activities

Knowledge and understanding (K)

A. Organizational

context (Knowledge

of the company /

organization and its

processes)

The individual on the job needs to know and understand:

KA1. organizational procedures

KA2. documentation and reporting as per organization’s mandate

KA3. security procedures to be followed

KA4. escalation matrix for reporting identified problems

KA5. risk and impact of not following defined procedures/work instructions

KA6. coding system followed to label cargo

KA7. IT system and ERP system of the organization

B. Technical

knowledge

The individual on the job needs to know and understand:

KB1. basics of operations in a port terminal, ICD and CFS

KB2. use of various cargo handling equipment

KB3. use of rope, flags and other manual equipment

KB4. vessel layout and loading and unloading activities

KB5. procedures of tank cleaning, cargo movement

KB6. requirements regarding handling of cargo

KB7. different type of vessels and cargo and container sizes

KB8. different type of cranes and MHEs – their capacities, constraints and usage

KB9. handling of hazardous and non-hazardous cargo – International Maritime

Dangerous Goods (IMDG) code

KB10. marking of material and people movement areas

KB11. stuffing and de-stuffing norms with respect to different cargo

KB12. special characteristics and handling requirements of shipments, if any

KB13. IMDG code

Skills (S)

C. Core skills/

generic skills

Reading skills

The user/individual on the job needs to know how to read:

SA1. written instructions

SA2. shiping manifest, Bill of Lading, shipping bills and related documents

SA3. ERP and computer generated reports

SA4. cargo stowage plans and vessel plans

SA5. SOPs and safety regulation manuals

Writing skills

The user/individual on the job needs to know how to write:

SA6. work-orders and instructions

SA7. checklist of activities, delays, undelivered items, contacts, etc

SA8. daily reports

Oral communication (listening and speaking skills)

The user/individual on the job needs to know how to:

SA9. communicate with customers, freight operators, transporters, shipping

companies, other supervisors and port authorities

SA10. communicate with cargo equipment operators and ground staff over VHF

radio

SA11. guide cargo handlers for smooth operations

D. Professional skills Decision making

The user/individual on the job needs to know how to:

SB1. decide on required workforce and equipment for performing a particular task

SB2. assess the environmental condition and type of cargo to assess if it is safe for

operations

SB3. resolve a problem quickly internally

SB4. prioritise shipments

SB5. decide on deployment of alternate resources when required

Plan and organize

The user/individual on the job needs to know how to:

SB6. plan and estimate the co-ordination required for resolving a querry.

SB7. maintain punctuality

SB8. respond to the client in a timely manner

SB9. prioritize and execute tasks based on client requirements

SB10. make work plans and resource allocation plans

SB11. make checks on execution of work plans

SB12. be a team player and achieve joint goals

Customer centricity

The user/individual on the job needs to know how to:

SB13. adhere to the customer timelines

SB14. address the urgency regarding shipments and activities

Problem solving

The user/individual on the job needs to know how to:

SB15. make adjustment to working requirements for difficult weathers and

hazardous goods

SB16. identify trends/common causes for delays, damages, etc.

SB17. co-ordinate and handle major issues with different departments

SB18. identify bottlenecks and operational problems and suggest remedial action

Analytical thinking

The user/individual on the job needs to know how to:

SB19. assess the resource requirement for a particular task at hand

SB20. assess and prepare for backup resources in case of delays

SB21. plan for cargo movement so that the resources and stroage space is optimally

utilised

Critical thinking

The user/individual on the job needs to know and understand how to:

SB22. resolve issues in a qucik and cost effective manner

SB23. develop work plans factoring in external factors

SB24. check that all security measures and safety protocals are followed at all times