Planner – Diamond Processing

SECTOR: GEMS & JEWELLERY

SUB-SECTOR: Diamond processing

OCCUPATION: Rough Assorting

REFERENCE ID: G&J/Q4205

ALIGNED TO: NCO-2015/NIL

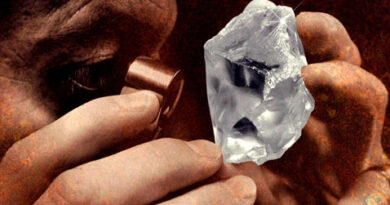

Brief Job Description: Individuals on this job use the designing software and

planning and marking machines to decide where to mark the diamond rough for

generating the most profitable polished diamond for the company as per its

policy of maximizing value or colour and weight retention.

Option 1 – Marker:

A marker needs to use his/her experience and make precise marking as the

accuracy of the following process depends on the accuracy of the marking. The

marking must be made with the objective of maximizing the value, or any other

as fixed by the company

Personal Attributes: The job requires the individual to have: attention to details;

good eyesight; ability to work for long hours in sitting position in front of the

computer; high level of concentration; and a lot of patience.

Keywords /Terms Description

Sector Sector is a conglomeration of different business operations having similar

business and interests. It may also be defined as a distinct subset of the economy

whose components share similar characteristics and interests.

Sub-sector Sub-sector is derived from a further breakdown based on the characteristics and

interests of its components.

Occupation Occupation is a set of job roles, which perform similar/ related set of functions

in an industry.

Job role Job role defines a unique set of functions that together form a unique

employment opportunity in an organisation.

Occupational Standards

(OS)

OS specify the standards of performance an individual must achieve when

carrying out a function in the workplace, together with the knowledge and

understanding they need to meet that standard consistently. Occupational

Standards are applicable both in the Indian and global contexts.

Performance Criteria Performance criteria are statements that together specify the standard of

performance required when carrying out a task.

National Occupational

Standards (OS)

NOS are occupational standards which apply uniquely in the Indian context.

Qualifications Pack (QP) QP comprises the set of OS, together with the educational, training and other

criteria required to perform a job role. A QP is assigned a unique qualifications

pack code.

Unit Code Unit code is a unique identifier for an Occupational Standard, which is denoted

by an ‘N’

Unit Title Unit title gives a clear overall statement about what the incumbent should be

able to do.

Description Description gives a short summary of the unit content. This would be helpful to

anyone searching on a database to verify that this is the appropriate OS they are

looking for.

Scope Scope is a set of statements specifying the range of variables that an individual

may have to deal with in carrying out the function which have a critical impact

on quality of performance required.

Knowledge and

Understanding

Knowledge and understanding are statements which together specify the

technical, generic, professional and organisational specific knowledge that an

individual needs in order to perform to the required standard.

Organisational Context Organisational context includes the way the organisation is structured and how

it operates, including the extent of operative knowledge managers have of their

relevant areas of responsibility.

Technical Knowledge Technical knowledge is the specific knowledge needed to accomplish specific

designated responsibilities.

Core Skills/ Generic

Skills

Core skills or generic skills are a group of skills that are the key to learning and

working in today’s world. These skills are typically needed in any work

environment in today’s world. In the context of the OS, these include

communication related skills that are applicable to most job roles.

Keywords /Terms Description

NOS National Occupational Standard(s)

NSQF National Skills Qualifications Framework

QP Qualifications Pack

Unit Code G&J/N4202

Unit Title

(Task) Plan the final cut of the diamond

Description This OS unit is about deciding the final dimensions of the rough diamond, in order to

maximize the return on investment for the company

Scope This unit/task covers the following:

Preparing the rough diamond for planning

Operating the software

Quality of planning

Achieving productivity

Controlling defects

Multitasking

Performance Criteria(PC) w.r.t. the Scope

Element Performance Criteria

Preparing the rough

diamond for planning

To be competent, the user/individual on the job must be able to:

PC1. analyse the rough diamond using an eye glass, draw a rough figure of the

diamond and record first observations such as colour, purity, etc.

PC2. mark and send the rough for windowing if required and check on receipt if

the windowing is as per requirement

PC3. fix the rough on a die pin with a glue meticulously and ensure it is an accord

with the alignment

PC4. apply whitener and place the rough in the laser mapping machine to create its

image without damaging it

PC5. remove from laser machine on creation of the image and clean it using

cleaning agents such as acetone

Operating the

software

PC6. ensure the designing of the rough diamond as done by using designing

software

PC7. create the image of the rough using the laser machine

PC8. enter the data of the parameters such as dimensions with diligence

Quality of planning PC9. decide the fate of a diamond and pick the optimum plan

PC10. extract maximum value from a particular rough as compared to others

PC11. ensure that no re-planning is required for any rough

PC12. mark the rough for cutting with accuracy

PC13. select the right method for inclusion plotting and rough cutting

PC14. label and bag the roughs packet before returning

Achieving

productivity

PC15. achieve the productivity in terms of carats or number of pieces as set by the

company

PC16. ensure, delivery for further processing is not delayed

Controlling defects PC17. ensure no damage to the rough during the planning process

PC18. spot and correct a faulty planning

PC19. asses that the marking is correct for the cut required and will not damage the

diamond

Multitasking PC20. work on multiple roughs at the same time and switch the planning quickly

depending on the type of rough

Knowledge and Understanding (K)

A. Organizational

Context

The user/individual on the job needs to know and understand:

KA1. Company’s policies on: acceptable limits of stone loss, incentives, delivery

standards, safety and hazards, integrity and personnel management

KA2. Non-disclosure of “confidential information” provided by the company either

orally or in writing marked as confidential

KA3. Liability arising out of loss, theft, or inadvertent disclosure of confidential

information

KA4. Work flow involved in gemstone processing of company

KA5. Importance of the individual’s role in the workflow

KA6. Reporting structure

KA7. Issue return procedures followed by the company

KA8. Typical customer profile and market trends

KA9. Specialization area of the company (size, clarity, shape, quality, etc. of

diamonds)

KA10. Diamond processing objective of the company, e.g. maximizing yield,

maximizing clarity, etc.

B. Technical

Knowledge

KB1. Computer and laser marking machine operations

KB2. Using different diamond planning software

KB3. Different types of diamond roughs and its properties

KB4. Rough assortment

KB5. Windowing process

KB6. Rough cutting process (Cleaving and Sawing)

KB7. Polishing process in the factory (Bruting, Blocking, Bottom, Top, Table,

Rounding, etc.)

KB8. Rough diamond shading – colour wise (LB-LC-White-Fancy)

KB9. Use of various scopes in diamond processing

KB10. Shape, cut, clarity, carat, colour and physical characteristics of the diamond

KB11. Tension in a diamond and use of tension machine

KB12. Fluorescence level of the diamond

KB13. Types of inclusions in a diamond

KB14. Inclusion planning methods (Box, IG, Galaxy, etc.) and its software

KB15. Spectrum process

KB16. File sharing on company’s server

KB17. Valuation of a diamond

KB18. Potential ways that may cause damage to a diamond

KB19. Potential work hazards, particularly, when using laser marking machine

KB20. Techniques of cutting a rough diamond

KB21. Windowing process

KB22. Bruting and polishing process

KB23. Use of various scopes in diamond processing

KB24. Geometry to understand the angles and symmetry

KB25. GIA diamond grading criteria

KB26. Repair work

Skills (S) [Optional]

A. Core Skills/

Generic Skills

Writing Skills

The user/ individual on the job needs to know and understand how to:

SA1. Document work done for status and performance appraisal

SA2. Document damage to the rough while marking as per companies rules

Reading Skills

SA3. To read descriptions on the diamond packets/ bags

SA4. Understand the results displayed by the computer and read manuals

Oral Communication (Listening and Speaking skills)

SA5. Discuss task, schedules, and work-loads with co-workers and supervisors

SA6. Understand instructions and report problems

SA7. Obtain approval from the supervisor for the final plan

SA8. Share work load as required

SA9. Assist others who require help

SA10. Share knowledge with co-workers

B. Professional Skills Decision Making

SB1. Decide the angles, size and shapes of the diamond

SB2. Make decisions pertaining to the inclusion plotting and the cutting technology

to be used

SB3. To decide the final plan to be selected for diamond polishing

SB4. To decide on the windowing, spectrum, etc. requirements

Plan and Organize

SB5. How to plan work for maximum productivity

SB6. How to plan the cut on the given rough to maximize return as per company’s

objectives

SB7. How to make various plans of the final cut diamond of different shapes, sizes,

colour, clarity and value

SB8. How to re plan the cut to obtain approval from supervisor

Customer Centricity

N.A.

Problem Solving

SB9. Refer inability to select method of inclusion plotting / cutting to reporting

authority to spot process disruptions and delays

SB10. Refer difficulty in plan selection to reporting authority

SB11. Refer damage to the rough while marking to reporting authority

SB12. Report about machine/ software failure to reporting authority

Analytical Thinking

SB13. Assess the accuracy of the inclusion plotting of the rough given

SB14. Analyze the options as per company’s objectives before final plan selection

SB15. Use the knowledge/experience about similar quality of roughs in the past to

predict the final outcome/quality of the current lot

SB16. Analyze the expected yield, clarity from the rough, while marking

Critical Thinking

SB17. Spot process disruptions and delays

Unit Code G&J/N9901

Unit Title

(Task) Coordinate with others

Description This OS unit is about communicating with colleagues, seniors and outside parties in

order to achieve the deliverables on schedule

Scope This unit/task covers the following:

Interacting with supervisor

Interacting with colleagues within and outside the department

Interacting with outside parties

Performance Criteria(PC) w.r.t. the Scope

Element Performance Criteria

Interacting with

supervisor

To be competent, the user/individual on the job must be able to:

PC1. coordinate for receiving work instructions and raw materials from reporting

supervisor

PC2. communicate to the reporting supervisor about process flow improvements,

product defects received from previous process, repairs and maintenance of

tools and machinery as required

PC3. communicate to reporting supervisor about operation details and hazards

PC4. interact with supervisor regarding compliance of company policy and rules

Interacting with

colleagues within and

outside the

department

PC5. coordinate with colleagues to share work, as per the workload

PC6. communicate and discuss work flow related difficulties in order to find

solutions with mutual agreement

PC7. coordinate and receive feedback from quality control department

PC8. coordinate for putting team goals over individual goals

PC9. resolve conflicts by communicating with colleagues and other departments

PC10. coordinate with colleagues regarding multitasking in other departments with

requirements

Interacting with

outside parties

PC11. adhere to nondisclosure policy of the company in all outside coordination

Knowledge and Understanding (K)

A. Organizational

Context

The user/individual on the job needs to know and understand:

KA1. Company’s policies on: preferred language of communication, reporting and

escalation policy, quality delivery standards, and personnel management

KA2. Company’s policies on non-disclosure of “confidential information” provided

by the company either orally or in writing marked as confidential

KA3. Liability arising out of loss, theft, or inadvertent disclosure of confidential

information

KA4. Reporting structure

KA5. Sharing knowledge with co-workers

B. Technical

Knowledge

KB1. Various categories of people that one is required to communicate and

coordinate within the organization

KB2. Importance of effective communication in the workplace

KB3. Importance of teamwork in organization and individual success

KB4. Various components of effective communication

KB5. Key elements of active listening

KB6. Barriers to effective communication

KB7. Importance of avoiding casual expletives and unpleasant terms while

communicating professional circles

KB8. Common reasons for interpersonal conflict

KB9. Expressing and addressing grievances appropriately and effectively

KB10. What constitutes disciplined behavior for a working professional

Skills (S) [Optional]

A. Core Skills/

Generic Skills

Writing Skills

The user/ individual on the job needs to know and understand how to:

SA1. Write instructions, remarks, job sheets, basic information, technical details

etc. in preferred local language of communication and English

Reading Skills

SA2. Read preferred language of communication as prescribed by the company

SA3. Read job sheets and interpret technical details mentioned in the job sheet

Oral Communication (Listening and Speaking skills)

SA4. Discuss task lists, schedules, and work-loads with co-workers

SA5. Be a good listener

SA6. Be effective in communicating the issues faced to the supervisor

SA7. Avoid using jargon, slang or acronyms when communicating

B. Professional Skills Decision Making

SB1. Spot and communicate potential areas of disruptions to work process and

report the same

SB2. Report to supervisor and or to deal with a colleague individually, depending

on the type of concern

Plan and Organize

SB3. Collate information and communicate in a manner that is clear and

comprehensive to colleagues and supervisor

Customer Centricity

SB4. Convey accurate information to all internal as well as external customers (or

right information to right person)

Coordinate with others

Problem Solving

SB5. How to handle critical situations caused due to communication issues at

workplace and solve problems without blaming others

Analytical Thinking

SB6. Analyse the work processes by interacting with others and adopting best

practices

SB7. Use prior experience to observe and reflect for development of ideas

Critical Thinking

SB8. Think through the problem, evaluate the possible solution(s) and suggest an

optimum /best possible solution(s)

SB9. Deal with clients lacking the technical background to solve the problem on

their own

SB10. Spot process disruptions and delays and report and communicate with

solutions

SB11. Identify immediate or temporary solutions to resolve delays

SB12. Apply, analyze, and evaluate the information gathered from observation,

experience, reasoning, or communication, as a guide to thought and action

Unit Code G&J/N9902

Unit Title

(Task) Maintain health and safety at workplace

Description This OS unit is about being aware of, communicating and taking steps towards

minimizing potential hazards and dangers of accidents on the job and maintaining

health and safety at workplace

Scope This unit/task covers the following:

Health and safety in work area

Fire safety

Emergencies, rescue and first aid procedures

Performance Criteria(PC) w.r.t. the Scope

Element Performance Criteria

Health and safety in

work area

To be competent, the user/individual on the job must be able to:

PC1. identify and use appropriate protective clothing/equipment for specific tasks

and work

PC2. identify hazardous job activities in his/her job and communicate the possible

causes of risks or accidents in the workplace

PC3. carry out safe working practices while dealing with hazards to ensure safety

of self and others

PC4. identify and avoid doing any tasks or activities in a bad working position

PC5. practice appropriate working postures to minimise occupational health

related issues

Fire safety PC6. use the appropriate fire extinguishers on different types of fire.

PC7. demonstrate rescue techniques applied during fire hazard

PC8. demonstrate good housekeeping in order to prevent fire hazards

PC9. demonstrate the correct use of any fire extinguisher

Emergencies, rescue

and first aid

procedures

PC10. administer appropriate first aid procedure to victims wherever required eg.in

case of bleeding, burns, choking, electric shock etc.

PC11. respond promptly and appropriately to an accident situation or medical

emergency

PC12. participate in emergency procedures such as raising alarm, safe evacuation,

correct means of escape, correct assembly point etc.

Knowledge and Understanding (K)

A. Organizational

Context

The user/individual on the job needs to know and understand:

KA1. Company’s policies on: safety and hazards and personnel management

KA2. Names and location of documents that refer to health and safety in work

place

KA3. Reporting structure

B. Technical

Knowledge

KB1. Meaning of “hazard’s” and risks

KB2. Health and safety hazards commonly present in the work place and related

precautions

KB3. Various dangers associate with use of electrical equipment

KB4. Preventative and remedial actions to be taken in case of exposure to toxic

material

KB5. Methods of accident prevention

KB6. How different chemicals react and what could be the danger from them

KB7. How to use machines and tools without suffering bodily harm

KB8. Importance of using protective clothing/ equipment while working

KB9. Precautionary activities to prevent the fire accident

KB10. Various causes of fire

KB11. Techniques of using different fire extinguishers

KB12. Different materials used for extinguishing fire

KB13. Rescue techniques applied during a fire hazard

KB14. Various types of safety signs and what they mean

KB15. Appropriate basic first aid treatment relevant to condition e.g. bleeding,

minor burns, eye injuries etc.

KB16. Potential impact to a person who is moved incorrectly

Skills (S) [Optional]

A. Core Skills/

Generic Skills

Writing Skills

The individual on the job needs to know and understand how to:

N.A.

Reading Skills

SA1. Read and comprehend basic content to read labels, charts, signage’s

SA2. Read and comprehend basic English to read manuals of operations

Oral Communication (Listening and Speaking skills)

SA3. Effectively communicate the risk

B. Professional Skills Decision Making

SB1. Report potential sources of danger

SB2. Follow the relevant prescribed procedure in the event of an accident

SB3. Wear appropriate safety gear to avoid an accident

Plan and Organize

SB4. Learn from past mistakes regarding use of hazardous machines or chemicals

Customer Centricity

N. A.

Problem Solving

SB5. Adhere to and guide others to follow prescribed procedures related to health

and safety at workplace

Analytical Thinking

SB6. Analyse untoward incidents from the past and implement correct use of

machines, tools or hazardous chemicals

Critical Thinking

SB7. Critically analyse the processes carried out by self and by colleagues in the

department to spot potential hazards and safety issues

Unit Title

(Task) Mark the rough diamond

Description This OS unit is about marking the rough diamonds for providing a line of action to

further processing like windowing, sawing, cleaving, etc. or for the purpose of

identification. A marker must make precise marking as the accuracy of the following

process depends on the accuracy of the marking. The marking must be made with the

objective of maximizing the value, or any other as fixed by the company.

Scope This unit/task covers the following:

Inspect and mark each rough diamond

Perform Quality check

Achieve productivity

Performance Criteria(PC) w.r.t. the Scope

Element Performance Criteria

Inspect and mark

each rough diamond

To be competent, the user/individual on the job must be able to:

PC1. scrutinize each rough individually through an eye glass and make the required

markings as per its classification, e.g. windowing mark, cleavable mark,

sawable mark, makeable mark

PC2. ensure that the marking is precise and the further process on the marking

should not damage the diamond

Perform quality

check

PC3. mark the roughs as per the company’s policies

PC4. detect and correct/repair a faulty marking

PC5. ensure no damage to the stone due to faulty marking

PC6. complete work with no loss of roughs

Achieve productivity PC7. achieve the productivity in terms of carats or number of pieces as set by the

company

PC8. deliver in time to next process

Knowledge and Understanding (K)

A. Organizational

Context

The user/individual on the job needs to know and understand:

KA1. Company’s policies on: acceptable limits of weight loss; incentives; delivery

standards; safety practices and hazards; security and performance

measurement

KA2. Work flow involved in company’s diamond processing process

KA3. Importance of the individual’s role in the workflow

KA4. Reporting structure

KA5. Issue return procedures followed by the company

KA6. Typical customer profile and market trends

KA7. Specialization area of the company (size, clarity, shape, quality, etc. of

diamonds)

KA8. Diamond processing objective of the company, e.g. maximizing yield,

maximizing clarity, etc.

B. Technical

Knowledge

KB1. Different types of diamond roughs and its properties

KB2. Rough assortment

KB3. Windowing process

KB4. Rough cutting process (Cleaving and Sawing)

KB5. Polishing process in the factory (Bruting, Blocking, Bottom, Top, Table,

Rounding, etc.)

KB6. 4Cs of diamond (Colour, Cut, Clarity and Carat)

KB7. Rough diamond shading – colour wise (LB-LC-White-Fancy)

KB8. Use of various scopes in diamond processing

KB9. Stress (tension) of the diamond

KB10. Types of diamond inclusions

KB11. Valuation as per market practice

KB12. Windowing process to look inside a rough

KB13. Repair work

Skills (S) [Optional]

A. Core Skills/

Generic Skills

Writing Skills

The user/ individual on the job needs to know and understand how to:

SA1. Document work done for status and performance appraisal

SA2. Report diamond losses via documentation as per company policy

Reading Skills

SA3. To read descriptions on the rough packets/ bags

Oral Communication (Listening and Speaking skills)

SA4. Receive the packet of roughs from the supervisor along with instructions

SA5. Discuss task lists, schedules, and work-loads with co-workers and supervisor

SA6. Understand instructions and report problems

B. Professional Skills Decision Making

SB1. Decide which plane to mark in order to achieve the company’s objective of

maximizing value and minimizing the damage to the rough

SB2. Decide the size of marking and the number of markings required

Plan and Organize

SB3. Make markings as per requirement on the rough

SB4. Plan and organize work in order to ensure maximum productivity

N.A.

Problem Solving

SB5. Detect and correct / repair a faulty marking

SB6. Suggest improvements in order to reduce loss

Analytical Thinking

SB7. Use the knowledge/experience about similar quality of roughs in the past to

predict the final outcome/quality of the current lot

SB8. Analyze the expected yield, clarity from the rough, while marking

SB9. Judge the planes, angles and other dimensions of the rough, to make

appropriate markings

SB10. Judge the extent of marking required for a particular type of rough (size of the

groove, cut, etc.)

SB11. Approximately estimate the value of the diamond

Critical Thinking

SB12. Spot process disruptions and delays

Criteria For Assessment Of Trainees

Job Role Planner – Diamond Processing

Qualification Pack G&J/Q4205

Sector Skill Council Gem & Jewellery

Guidelines for Assessment

- Criteria for assessment for each Qualification Pack will be created by the Sector Skill Council. Each Performance

Criteria (PC) will be assigned marks proportional to its importance in NOS. SSC will also lay down proportion of

marks for Theory and Skills Practical for each PC. - The assessment for the theory part will be based on knowledge bank of questions created by the SSC.

- Assessment will be conducted for all compulsory NOS, and where applicable, on the selected elective/option

NOS/set of NOS. - Individual assessment agencies will create unique question papers for theory part for each candidate at each

examination/training center (as per assessment criteria below). - Individual assessment agencies will create unique evaluations for skill practical for every student at each

examination/training center based on this criterion. - To pass the Qualification Pack, every trainee should score a minimum of 70% of aggregate marks to successfully

clear the assessment. - In case of unsuccessful completion, the trainee may seek reassessment on the Qualification Pack.