Free Machining Assistant Course (6Months)

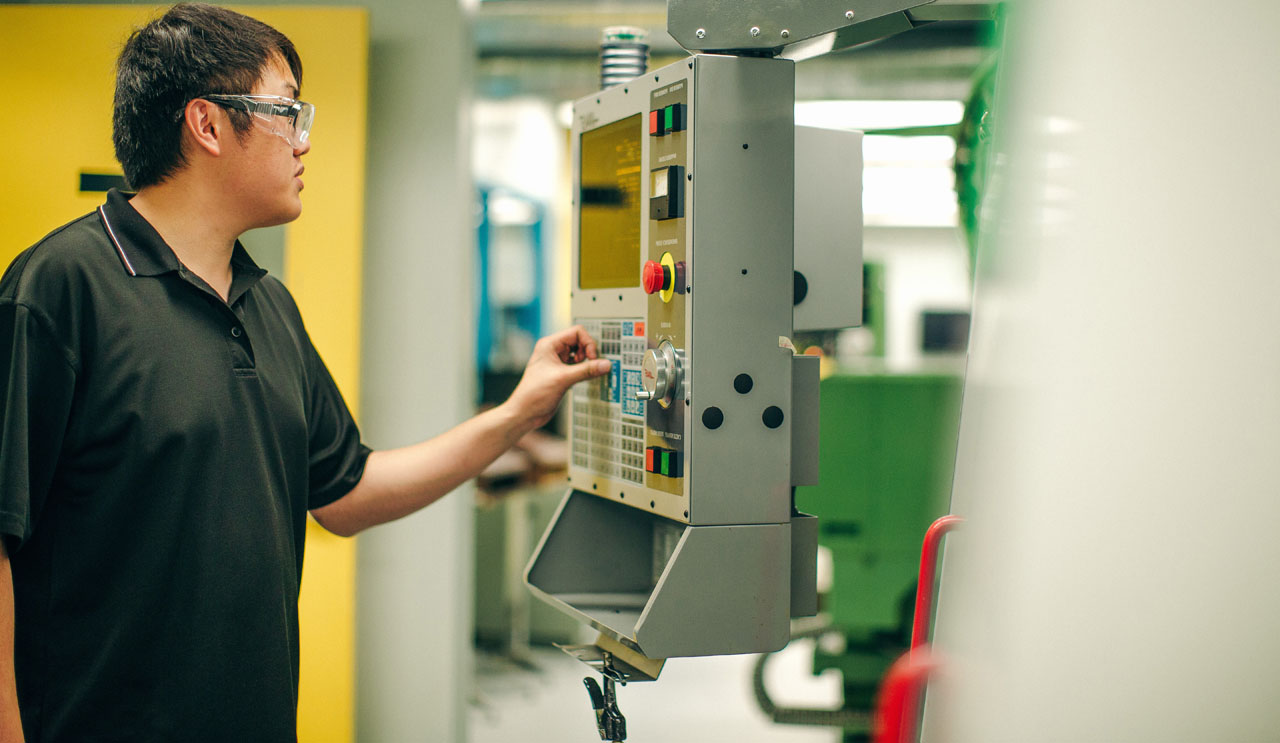

Machining Assistant/Helper Level 2:

Brief Job Description

The Helper role is responsible for small time routine jobs like cleaning, washing, fetching and holding tool for the operators, loading and unloading of work pieces on the machine setup , bringing raw material and spare parts from the stores etc.

Personal Attributes

Basic understanding of the machining and housekeeping process, Basic reading, writing and communication skills, safety orientation, ability to do physical tasks like lifting, holding etc- Ability to lift objects required during the operations either manually or using lifts, chains without displaying fatigue, hands and feet dexterity, good vision.

Maintain a safe and healthy working environment:

Elements and Performance Criteria

Identify and report the risks identified

To be competent, the user/individual on the job must be able to:

PC1.. Identify activities which can cause potential injury through sharp objects, burns, fall, electricity, gas leakages, radiation, poisonous fumes, chemicals ,loud noise

PC2. Inform the concerned authorities about the potential risks identified in the processes, workplace area/ layout, materials used etc

PC3. Inform the concerned authorities about machine breakdowns, damages which can potentially harm man/ machine during operations

PC4. Create awareness amongst other by sharing information on the identified risks

Create and sustain a Safe, clean and environment friendly work place

To be competent, the user/individual on the job must be able to:

PC5.. Follow the instructions given on the equipment manual describing the operating process of the equipments

PC6.. Follow the Safety, Health and Environment related practices developed by the organization

PC7. Operate the machine using the recommended Personal Protective Equipments (PPE)

PC8. . Maintain a clean and safe working environment near the work place and ensure there is no spillage of chemicals, production waste, oil, solvents etc

PC9. Maintain high standards of personal hygiene at the work place

PC10. Ensure that the waste disposal is done in the designated area and manner as per organization SOP.

PC11. Inform appropriately the medical officer/ HR in case of self or an employees illness of contagious nature so that preventive actions can be planned for others

Knowledge and Understanding (KU)

The individual on the job needs to know and understand:

KU1. relevant standards, procedures and policies related to Health, Safety and Environment followed in the company

KU2. basic knowledge of Safety procedures( fire fighting, first aid) within the organization

KU3. knowledge of various types of PPEs and their usage

KU4. basic knowledge of risks/hazards associated with each occupation in the organization

KU5. how to safely operate various tools and machines and risksassociated with the tools/ equipment

KU6. knowledge of personal hygiene and how an individual an contribute towards creating a highly safe and clean working environment

Generic Skills (GS)

User/individual on the job needs to know how to:

GS1. write basic level notes and observations

GS2. read safety instructions put up across the plant premises

GS3. read safety precautions mentioned in equipment manuals and panels to understand the potential risks associated

GS4. effectively communicate information to team members

GS5. informemployees in the plant and concerned functions about events, incidents & potential risks observed related to Safety, Health and Environment.

GS6. question operator/ supervisor in order to understand the safety related issues

GS7. attentively listen with full attention and comprehend the information given by the speaker during safety drills and training programs

GS8. use common sense and make judgments during day to day basis

GS9. use reasoning skills to identify and resolve basic problems

GS10. use common sense and make judgments during day to day basis

GS11. use reasoning skills to identify and resolve basic problems

Maintain 5S at the work premises:

Elements and Performance Criteria

Ensure sorting

To be competent, the user/individual on the job must be able to:

PC1.. follow the sorting process and check that the tools, fixtures & jigs that are lying on workstations are the ones in use and unnecessary items are not cluttering the workbenches or work surfaces.

PC2.. ensure segregation of waste in hazardous/ non hazardous waste as per the sorting work instructions

PC3.. follow the technique of waste disposal and waste storage in the proper bins as per sop

PC4.. segregate the items which are labelled as red tag items for the process area and keep them in the correct places

PC5. sort the tools/ equipment/ fasteners/ spare parts as per specifications/ utility into proper trays, cabinets, lockers as mentioned in the 5s guidelines/ work instructions

PC6. . ensure that areas of material storage areas are not overflowing

PC7. properly stack the various types of boxes and containers as per the size/ utility to avoid any fall of items/ breakage and also enable easy sorting when required

PC8. return the extra material and tools to the designated sections and make sure that no additional material/ tool is lying near the work area

PC9. follow the floor markings/ area markings used for demarcating the various sections in the plant as per the prescribed instructions and standards

PC10. follow the proper labeling mechanism of instruments/ boxes/ containers and maintaining reference files/ documents with the codes and the lists

Ensure proper documentation and storage ( organizing , streamlining)

To be competent, the user/individual on the job must be able to:

PC11. check that the items in the respective areas have been identified as broken or damaged

PC12. follow the given instructions and check for labelling of fluids, oils. lubricants, solvents, chemicals etc. and proper storage of the same to avoid spillage, leakage, fire etc

PC13. make sure that all material and tools are stored in the designated places and in the manner indicated in the 5s instructions

Ensure cleaning of self and the work place

To be competent, the user/individual on the job must be able to:

PC14. check whether safety glasses are clean and in good condition

PC15. keep all outside surfaces of recycling containers are clean

PC16.. ensure that the area has floors swept, machinery clean and generally clean. in case of cleaning, ensure that proper displays are maintained on the floor which indicate potential safety hazards

PC17.. check whether all hoses, cabling & wires are clean, in goodcondition and clamped to avoid any mishap or mix up

PC18.. ensure workbenches and work surfaces are clean and in good condition

PC19. follow the cleaning schedule for the lighting system to ensure proper illumination

PC20. store the cleaning material and equipment in the correct location and in good condition

PC21. ensure self-cleanliness – clean uniform, clean shoes, clean gloves, clean helmets, personal hygiene

Ensure sustenance

To be competent, the user/individual on the job must be able to:

PC22. follow the daily cleaning standards and schedules to create a clean working environment

PC23. attend all training programs for employees on 5 s

PC24. support the team during the audit of 5 s

PC25. participate actively in employee work groups on 5s and encourage team members for active participation

PC26. follow the guidelines for what to do and what not to do to build sustainability in 5s as mentioned in the 5s check lists/ work instructions

Knowledge and Understanding (KU)

The individual on the job needs to know and understand:

KU1. relevant standards, procedures and policies related to 5S followed in the company

KU2. have basic knowledge of 5S procedures

KU3. know various types 5s practices followed in various areas

KU4. understand the 5S checklists provided in the department/ team

KU5. have skills to identify useful & non useful items

KU6. have knowledge of labels , signs & colours used as indicators

KU7. knowledge on how to sort and store various types of tools, equipment, material etc.

KU8. know , how to identify various types of waste products

KU9. understand the impact of waste/ dirt/ dust/unwanted substances on the process/ environment/ machinery/ human body

KU10. have knowledge of best ways of cleaning & waste disposal

KU11. understand the importance of standardization in processes

KU12. understand the importance of sustainability in 5S

KU13. have knowledge of TQM process

KU14. have knowledge of various materials and storage norms

KU15. understand visual controls, symbols, graphs etc.

Generic Skills (GS)

User/individual on the job needs to know how to:

GS1. write basic level notes and observations

GS2. note down observations (if any) related to the process

GS3. read 5S instructions put up across the plant premises

GS4. effectively communicate information to team members inform employees in the plant and concerned functions about 5S

GS5. question the process head in order to understand the 5S related issues

GS6. attentively listen with full attention and comprehend the information given by the speaker during 5S training programs

GS7. use common sense and make judgments during day to day basis

GS8. use reasoning skills to identify and resolve basic problems using 5S

GS9. persuade co team members to follow 5 S

GS10. ensure that the co team members understand the importance of using 5 S tool

GS11. use innovative skills to perform and manage 5 S activities at the work desk and the shop floor

GS12. exhibit inquisitive behaviour to seek feedback and question on the existing set patterns of work

GS13. do what is right, not what is a popular practices

GS14. follow shop floor rules& regulations and avoid deviations; make 5S an integral way of life

GS15. ensure self-cleanliness on a daily basis

GS16. demonstrate the will to keep the work area in a clean and orderly manner

Support the machinist in the routine machining activities:

Elements and Performance Criteria

Fetching and holding tools for the operator

To be competent, the user/individual on the job must be able to:

PC1. . bring right toolkits for the operator and check whether all required tools are available in the tool kit

PC2. . hold the tools during operations in the correct manner as specified by the operator and the standard operating procedures so that the operator can easily complete the assigned job

Loading work pieces on the machines using fasteners and hand tools

To be competent, the user/individual on the job must be able to:

PC3. . support the assistant operator in arranging the work pieces in the specified manner as given in the setting document

PC4. . ensure that there is no damage done to the work pieces while loading them on the machining apparatus using pulleys, chains and other hoisting mechanisms

Replace worn tools and sharpen dull cutting tools and dies

To be competent, the user/individual on the job must be able to:

PC5. . use bench grinders and cutting grinder machines to replace the tools and dies

Support the assistant operator/ machinist in machine operations

To be competent, the user/individual on the job must be able to:

PC6. . use templates , measuring instruments and hand tools for the process of installation and adjustment of drills, cutters, dies and guides

PC7. . adjust tool positions and machine control mechanisms through the cranking (turning) process to ensure clearances and tolerances as specified in the operating manual

PC8. . extract the jammed pieces using fingers, wire hooks and lift bars

Maintenance and cleaning of machine and workplace

To be competent, the user/individual on the job must be able to:

PC9. . store equipment auxiliaries and spare parts in proper designated areas

PC10. . regularly clean the equipment and process auxiliaries (cutting tools, dies) to remove any dust, moisture, waste material which would have got collected on the equipment and remove the metal chips and extra coolant

PC11. . regularly clean the working area in the weld shop and create a healthy, clean and safe working environment

Knowledge and Understanding (KU)

The individual on the job needs to know and understand:

KU1. relevant standards and procedures followed in the company

KU2. different types of products manufactured by the company

KU3. different types of machining processes

KU4. different types of tools used in the machining process

KU5. basic principles of 5 S in manufacturing Cleaning, sorting

KU6. the application of coolants ad lubricants

KU7. basic Arithmetic and calculation methods

Generic Skills (GS)

User/individual on the job needs to know how to:

GS1. write basic level notes and observations

GS2. draw basic level drawings and charts

GS3. read documents and notes

GS4. interpret/ Comprehend the information given in the documents and notes

GS5. read and interpret symbols given on equipment and work area

GS6. discuss task lists and job requirements with co-workers

GS7. effectively communicate information to team members

GS8. question operator/ supervisor in order to understand the nature of the problem

GS9. attentively listen with full attention and comprehend the information given by the speaker

GS10. plan and organize the activities/ work allocated by supervisor and operator

GS11. organize all equipment and kits so that sorting is easy on a day to day basis

GS12. use common sense and make judgments during day to day basis

GS13. use reasoning skills to identify and resolve basic problems

GS14. follow instructions and work on areas of improvement identified

GS15. complete the assigned tasks with minimum supervision

GS16. complete the job defined by the supervisor within the timelines and quality norms

GS17. refer problems outside area of responsibility to appropriate person

Support the machinist in post machining process:

Elements and Performance Criteria

Unloading work pieces on the machines

To be competent, the user/individual on the job must be able to:

PC1. . support the assistant operator in removing the output products from the machining apparatus in the specified manner as given in the setting document

PC2. . use lifting tools like lifts, pulleys, chains, hoists and ensure that there is no damage done to the machined pieces while un loading them

Do Debarring

To be competent, the user/individual on the job must be able to:

PC3. . with the help of the correct tool remove the extra burrs and chips from the metal surface

Check quality of the machined pieces (Gauging)

To be competent, the user/individual on the job must be able to:

PC4. . support the assistant operator in measuring the specifications of the finished product using devices like micrometers, vernier calipers, gauges, rulers, weighing scales and any other inspection equipment

PC5. . bring right inspection tools for the operator and check whether all required tools are available near the inspection platform

PC6. . support the operator/ asst. operator in noting down the observations of the basic inspection process and identify pieces which are ok and also not meeting the specified standards

PC7. . separate the defective pieces into two categories pieces which can be repaired/ modified and pieces which are beyond repair and maintain records of each category

Knowledge and Understanding (KU)

The individual on the job needs to know and understand:

KU1. relevant standards and procedures followed in the company

KU2. different types of products manufactured by the company

KU3. basic norms for Quality in Production process

KU4. different types of machining processes

KU5. different types of tools used in the measurement and inspection process

KU6. different tools used for lifting objects

KU7. basic principles of 5 S in manufacturing Cleaning, sorting

KU8. basic Arithmetic and calculation methods

Generic Skills (GS)

User/individual on the job needs to know how to:

GS1. write basic level notes and observations

GS2. draw basic level drawings and charts

GS3. read documents and notes

GS4. interpret/ Comprehend the information given in the documents and notes

GS5. read and interpret symbols given on equipment and work area

GS6. discuss task lists and job requirements with co-workers

GS7. effectively communicate information to team members

GS8. question operator/ supervisor in order to understand the nature of the problem

GS9. attentively listen with full attention and comprehend the information given by the speaker

GS10. organize the activities/ work allocated by supervisor and operator

GS11. organize all equipment and kits so that sorting is easy on daily basis

GS12. use common sense and make judgments during day to day basis

GS13. use reasoning skills to identify and resolve basic problems

GS14. follow instructions and work on areas of improvement identified

GS15. complete the assigned tasks with minimum supervision

GS16. complete the job defined by the supervisor within the timelines and quality norms

GS17. ability to identify defective parts in the manufacturing line by comparing manufactured pieces with the work standard

Assessment Guidelines:

- Criteria for assessment for each Qualification Pack will be created by the Sector Skill Council. Each Element/ Performance Criteria (PC) will be assigned marks proportional to its importance in NOS. SSC will also lay down proportion of marks for Theory and Skills Practical for each Element/ PC.

- The assessment for the theory part will be based on knowledge bank of questions created by the SSC.

- Assessment will be conducted for all compulsory NOS, and where applicable, on the selected elective/option NOS/set of NOS.

- Individual assessment agencies will create unique question papers for theory part for each candidate at each examination/training center (as per assessment criteria below).

- Individual assessment agencies will create unique evaluations for skill practical for every student at each examination/ training center based on these criteria.

- To pass the Qualification Pack assessment, every trainee should score the Recommended Pass % aggregate for the QP.

- In case of unsuccessful completion, the trainee may seek reassessment on the Qualification Pack.