Free Fabric Cutter Course(1year Diploma)

Fabric Cutter click here

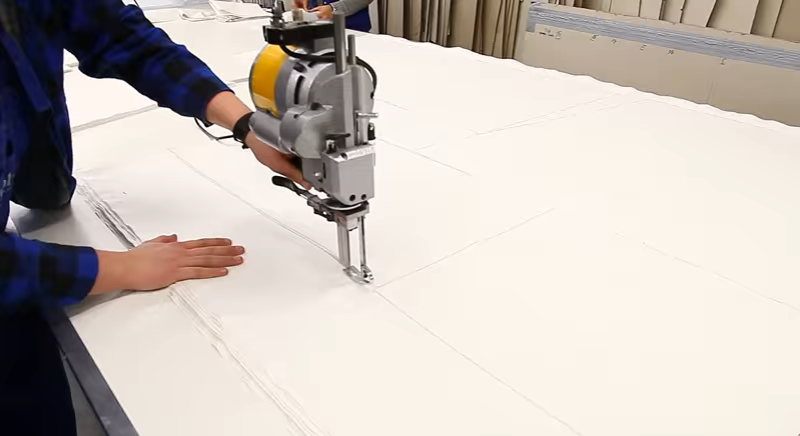

The fabric cutter for apparel, made-ups and home furnishing is a job role in cutting section responsible for cutting of fabric layers as per pattern marked onto the fabric or paper with the help of handheld electrical cutter or manually.

Brief Job Description:- The Fabric Cutter (apparel, made-ups and home furnishing) is responsible for bulk cutting with precision of fabrics manually or with the help of electrically operated fabric cutter keeping the pattern placement on the marker and various markings and specifications like style number, name, notches, etc. in mind.

Personal Attributes: -He/she should have good eye sight, immune from colour blindness, patient and focused to task. He should be keen looking for details. He/she should have basic mathematical skills, particularly making arithmetical calculations and measurement.

He/she should possess good oral communication skills in simple English and vernacular. He/she should have tenacity to work under pressure Fabric Cutter Course.

Preparatory checks to fabrics and Basic calculations related to layering and fabric consumption Fabric Cutter Course:-

PC1. Check the fabrics for defects for severity and quantity like holes, stains, slubs, missing pick, etc.

PC2. Calculate the number of componentsto be cut for a particular style as per job card

PC3. Calculate the quantity of fabrics needed against the job card received PC4. Check for marker types as per fabric lay forms

PC5. Lay the fabrics in such a way so as to ensure the wastages is within defined tolerance PC6. Spread the marker on the lay

Cutting of fabrics belonging to the product category of apparel, made-ups and home furnishing:-

PC1. Ensure the fabric lays are clipped at suitable points to restrict sliding of fabric layers during cutting

PC2. Cut the fabric layers manually or with electrically operated cutting equipments like band knife, straight knife, etc. as per mentioned in the job card

PC3. Identify the cut parts, count tickets and then group them well to pass on Fabric Cutter Course.

PC4. Ensure the bundled tickets have all the necessary information like style number, cut piece name, etc

Hazards and risks associated with the process(es), medical emergencies and evacuation process Fabric Cutter Course:-

PC1. Ensure safe and secure handling of cutting tools

PC2. Ensure use of safety measure and/or device to cutting of fabric with electrical handheld cutter like mesh gloves, etc.

PC3. Monitor the workplace and work processes for potential risks and threats such as physical injuries or disability, etc.

PC4. Participate in mock-drills/evacuation procedures organized at the workplace

PC5. Undertake first-aid, fire-fighting and emergency response training

Maintaintheworkarea, tools and machines Fabric Cutter Course:- To be competent, the user/individual on the job must be able to:

PC1. Handle materials, machinery, equipment and tools safely and correctly Fabric Cutter Course.

PC2. Use correct lifting and handling procedures PC3. Use materials to minimize waste

PC4. Maintain a clean and hazard free working area

PC5. Maintain tools and equipment

PC6. Carry out running maintenance within agreed schedules

PC7. Carry out maintenance and/or cleaning within one’s responsibility

PC8. Report unsafe equipment and other dangerous occurrences

PC9. Ensure that the correct machine guards are in place

PC10.Work in a comfortable position with the correct posture Fabric Cutter Course.

PC11.Use cleaning equipment and methods appropriate for the work to be carried out

PC12.Dispose of waste safely in the designated location

PC13. Store cleaning equipment safely after use

PC14.Carry out cleaning according to schedules and limits of responsibility

Comply with industry, and organizational requirements Fabric Cutter Course:- To be competent, the user/individual on the job must be able to:

PC1. Carry out work functions in accordance with legislation and regulations, organizational guidelines and procedures

PC2. Seek and obtain clarifications on policies and procedures, from your supervisor or other authorized personnel

PC3. Apply and follow these policies and procedures within your work practices Fabric Cutter Course.

PC4. Provide support to your supervisor and team members in enforcing these considerations

PC5. Identify and report any possible deviation to these requirements

Guidelines for Assessment:-

- Criteria for assessment for each Qualification Pack will be created by the Sector Skill Council. Each Performance Criteria (PC) will be assigned marks proportional to its importance in NOS. SSC will also lay down proportion of marks for Theory and Skills Practical for each

PC 2. The assessment for the theory part will be based on knowledge bank of questions approved by the

SSC 3. Individual assessment agencies will create unique question papers for theory part for each candidate at each examination/training center (as per assessment criteria below)

4. Individual assessment agencies will create unique evaluations for skill practical for every student at each examination/training center based on this criteria Fabric Cutter Course.

5. To pass the Qualification Pack, every trainee should score a minimum of 70% aggregate in a QP

6. In case of successfully passing only certain number of NOS’s, the trainee is eligible to take subsequent assessment on the balance NOS’s to pass the Qualification Pack

(Plan and Prepare the process of cutting fabrics as per the job card received) Fabric Cutter Course:-

PC1. Check the fabrics for defects for severity and quantity like holes, stains, slubs, missing pick, etc.

PC2. Calculate the number of components to be cut for a particular style as per job card

PC3. Calculate the quantity of fabrics needed against the job card received

PC4. Check for marker types as per fabric lay forms

PC5. Lay the fabrics in such a way so as to ensure the wastages is within defined tolerance

PC6. Spread the marker on the lay

(Cut fabrics as per plan received from production planning):-

PC1. Ensure the fabric lays are clipped at suitable points to restrict sliding of fabric layers during cutting Fabric Cutter Course.

PC2. Cut the fabric layers manually or with electrically operated cutting equipments like band knife, straight knife, etc. as per mentioned in the job card

PC3. Identify the cut parts, count tickets and then group them well to pass on

PC4. Ensure the bundled tickets have all the necessary information like style number, cut piece name, etc.

(Maintain health, saftety and security in the cutting workplace):-

PC1. Ensure safe and secure handling of cutting tools

PC2. Ensure use of safety measure and/or device to cutting of fabric with electrical handheld cutter like mesh gloves, etc

PC3. Monitor the workplace and work processes for potential risks and threats such as physical injuries or disability, etc.

PC4. Participate in mockdrills/evacuation procedures organized at the workplace

PC5. Undertake first-aid, firefighting and emergency response training Fabric Cutter Course.

(Maintain workarea, tools and machines):-

PC1. Handle materials, machinery, equipment and tools safely and correctly

PC2. Use correct lifting and handling procedures

PC3. Use materials to minimize waste

PC4. Maintain a clean and hazard free working area

PC5. Maintain tools and equipments

PC6. Carry out running maintenance within agreed schedules

PC7. Carry out maintenance and/or cleaning within one’s responsibility

PC8. Report unsafe equipment and other dangerous occurrences

PC9. Ensure that the correct machine guards are in place

PC10. Work in a comfortable position with the correct posture Fabric Cutter Course.

PC11. Use cleaning equipment and methods appropriate for the work to be carried out

PC12. Dispose of waste safely in the designated location

PC13. Store cleaning equipment safely after use

PC14. Carry out cleaning according to schedules and limits of responsibility

(Comply with industry, regulatory and organizational requirements):-

PC1. Carry out work functions in accordance with legislation and regulations, organizational guidelines and procedures

PC2. Seek and obtain clarifications on policies and procedures, from your supervisor or other authorized personnel

PC3. Apply and follow these policies and procedures within your work practices

PC4. Provide support to your supervisor and team members in enforcing these considerations

PC5. Identify and report any possible deviation to these requirements

Organizational Context:-

The user/individual on the job needs to know and understand:

KA1. Personal hygiene and duty of care

KA2. Safe working practices and organizational procedures

KA3. Limits of your own responsibility Fabric Cutter Course.

KA4. Ways of resolving with problems within the work area

KA5. The production process and the specific work activities that relate to the whole process KA6. The importance of effective communication with colleagues

KA7. The lines of communication, authority and reporting procedures

KA8. The organization’s rules, codes and guidelines (including timekeeping)

KA9. The company’s quality standards

KA10. The importance of complying with written instructions

KA11. Equipment operating procedures / manufacturer’s instructions

Technical Knowledge:-

The user/individual on the job needs to know and understand:

KB1. Work instructions and specifications and interpret them accurately

KB2. Method to make use of the information detailed in specifications andinstructions

KB3. Relation between work role and the overall manufacturing process

KB4. The importance of taking action when problems are identified

KB5. Different ways of minimizing waste

KB6. The importance of running maintenance and regular cleaning

KB7. Effects of contamination on products i.e. Machine oil, dirt

KB8. Common faults with equipment and the method to rectify

KB9. Maintenance procedures KB10. Hazards likely to be encountered when conducting routine maintenance

KB11. Different types of cleaning equipment and substances and their use

KB12. Safe working practices for cleaning and the method of carrying them out

Core Skills/ Generic Skills:- The user/individual on the job needs to know and understand how to:

SA1. Write and document appropriate technical forms, job cards, inspection sheets as required format of the company

Reading Skills:- The user/individual on the job needs to know and understand how to:

SA2. Read and comprehend basic English to read and interpret indicators in the machine and operating manuals, job cards, visual cards

SA3. Read and understand manuals, health and safety instructions, memos, reports, job cards, etc

Oral Communication (Listening and Speaking skills):-

The user/individual on the job needs to know and understand how to:

SA4. Speak and communicate effectively to peers and supervisors

SA5. Give clear instructions to co-workers, subordinates, others

SA6. Use correct technical term while interacting with supervisor

Professional Skills:-

The user/individual on the job needs to know and understand how to:

SB1. Take appropriate decisions regarding to responsibilities

SB2. Assess for any damage/faulty component in the concerned machinery and take action accordingly

SB3. Evaluate the decision and conduct basic trouble shooting

Plan and Organize:-

The user/individual on the job needs to know and understand how to:

SB4. Plan and manage work routine based on company procedure

SB5. Work with supervisors/team mates to carry out work related tasks

SB6. Plan for cleaning and lubricating the concerned machinery daily

SB7. Plan for cleaning the concerned tools and workplace daily before and after operations

Customer Centricity:-

The user/individual on the job needs to know and understand how to:

SB8. Ensure and follow organizational procedures pertaining to health and safety are followed

Problem Solving:- The user/individual on the job needs to know and understand how to:

SB9. Solve operational role related issues

Analytical Thinking:- The user/individual on the job needs to know and understand how to:

SB10. Diagnose common problems in the machine based on visual inspection, sound, temperature, etc.

Critical Thinking:- The user/individual on the job needs to know and understand how to:

SB11. Analyze, evaluate and apply the information gathered from observation, experience, reasoning or communication to act efficiently

Plan for the fabric cutting process:-

Describe basic textile terminology, types of

· fabrics and their trade names like chiffon, georgette, poly-cotton, etc. Describe fabric characteristics like feel,

· structure, construction, grain line, etc. Describe types of fabric defects like holes,

· stains, slubs etc. Describe layering/spreading defects like faulty

· prints, wrong method adopted, etc. Interpret work instructions and specifications

· accurately. Interpret equipment operating procedures/

· manufacturer’s instructions. Describe methods to make use of the

· information detailed in the specifications and instructions. Describe the organization’s rules, codes and

· guidelines (including timekeeping). Calculate the quantity of fabrics needed

· against the job card received. Calculate the number of components to be cut

· for a particular style as per job card. Describe various layering and spreading

· processes. Describe various types of patterns, markers,

· tools and methods required for marking.

Basic calculations related to layering and fabric consumption:-

Explain different types of fabric laying

· techniques like straight lay, stepped lay, etc. Identify the best fabric laying technique so

· to minimize wastages. Select marker type as per fabric lay forms.

· Lay the fabrics in such a way to ensure that

· the wastage is within the defined tolerance. Spread the marker sheet on the fabric that is

· laid out. Identify the type of cutting machine which

· offers better productivity with lesser wastage of materials and time.

Prepare for cutting fabrics:-

Ensure the availability of the different types of

· cutting machines in the organization. List organization’s policies and procedures

· with respect to fabric cutting. Identify fabrics required as per cutting plan

· and delivery priority. Organize fabrics in a defined sequence as per

· cutting plan and delivery priority. Check the fabrics for defects with respect to

· severity and quantity like presence of holes, stains, slubs, missing pick, etc. Ensure that the correct machine guards are in

· place. Handle materials, machinery, equipment and

· tools safely and correctly. List different specifications mentioned on a

· pattern and on bundle tickets like style

number, pattern name, size, etc. Identify protocol and format for reporting

· work/machine related risks/problems.

Fabric cutting operation:-

Ensure the fabric lays are clipped at suitable

· points to restrict sliding of fabric layers during cutting. Cut the fabric layers manually and with

· electrically operated cutting equipment like band knife, straight knife, etc. as mentioned in the job card. Identify the cut parts, count tickets and then

· group them well to pass on. Ensure the bundled tickets have all the

· necessary information like style number, cut piece name, etc. Describe how to rectify different faults that

· occur in cutting machines while cutting fabrics. Explain the importance of taking appropriate

· action when problems are identified. Identify consequences of not identifying and

· rectifying problems.

Maintain health, safety and security at workplace:-

Explain health and safety related practices

· applicable at the workplace. Describe layout of the plant and details of

· emergency exits, escape routes, emergency equipment and assembly points. Describe environmental management system

· related procedures at the workplace. Follow environment management system

· related procedures. Comply with health and safety related

· instructions applicable in the workplace. List potential hazards, risks and threats based

· on nature of operations. List occupational health and safety risks and

· methods. Describe potential accidents, emergencies

· and responses to these scenarios. Monitor the workplace and work processes for

· potential risks and threats. Ensure the work area is free from potential

· hazards. Report hazards and potential risks/ threats to

· supervisors or other authorized personnel. Carry out a periodic walk-through to keep

· work area free from hazards and obstructions. Seek clarifications, from supervisors or other

· authorized personnel in case of perceived risks. State reporting protocol and documentation

· required. State organizational procedures for safe

· handling of equipment and machine

operations. Explain various personal protective equipment

· and their method of use. Use appropriate personal protective

· equipment as per protocol. Report unsafe equipment and other

· dangerous occurrences. Describe identification, handling and storage

· of hazardous substances. Describe elements of proper disposal system

· for waste and by-products. Identify signage related to health and safety

· and their meaning. State details of personnel trained in first aid,

· fire-fighting and emergency response. Describe actions to take in the event of a

· mock drill/ evacuation procedures or actual accident, emergency or fire. Participate in mock drills/ evacuation

· procedures organized at the workplace. Undertake first aid, fire-fighting and

· emergency response training. Take action based on instructions in the event

· of fire, emergencies or accidents. Follow organization procedures for shutdown

· and evacuation when required. Carry out own activities in line with approved

· guidelines and procedures. Minimize health and safety risks to self and

· others due to own actions. Identify and correct (if possible) malfunctions

· in machinery and equipment. Report any service malfunctions that cannot

· be rectified. Store materials and equipment in line with

· manufacturer’s and organizational requirements. Safely handle and move waste and debris

.· State importance of sound health, hygiene

· and good habits. Describe ill-effects of alcohol, tobacco and

· drugs. Maintain a healthy lifestyle and guard against

· dependency on intoxicants. Demonstrate basic first aid

.· Demonstrate basic CPR

Maintain work area, tools and machines:-

Describe safe working practices for cleaning

· and maintenance of equipment. Describe effects of contamination on products

· i.e. Machine oil, dirt etc. Identify different types of cleaning equipment

· and substances and their use. Describe various machines used for layering

· and spreading processes

Describe various markers and tools that are

· required for marking. Describe different types of cutting machines

· like scissors, straight knife, band knife, laser cutting machine, etc. List procedures to conduct maintenance of

· tools and equipment. Handle materials and tools safely and

· correctly. Use cleaning equipment and methods

· appropriate for the work to be carried out. Identify common faults with equipment and

· the method to rectify. Use correct lifting and handling procedures.

·

Carry out regular running maintenance of

· tools and equipment within agreed schedules and limits of responsibility. Carry out safe working practices for cleaning

· and maintenance of equipment. Maintain a comfortable position with correct

· posture while working. Identify different ways of minimizing wastage.

· Dispose off waste safely in the designated

·

location. Carry out cleaning according to schedules

· and limits of responsibility. Store cleaning equipment safely at the

· designated place after use. Explain the importance of effective

· communication with colleagues and supervisors. Describe the lines of communication, authority

· and reporting procedures. Describe the company’s quality standards.

·

Describe the types of records kept and the

· methods to complete the records. Describe the importance of keeping accurate

· quality records. Describe the importance of complying with

· written instructions. Report quality issues to appropriate people

· State the importance of keeping accurate

·

records concerning quality. State safe working practices and

· organizational procedures. Describe limits of self-responsibility

.· Describe ways of resolving problems within

· the work area.

Comply with Industry, regulatory and organizational requirements:-

State the importance of having an ethical and

· value-based approach. State the benefits of following organizational

· norms for values and ethics. State the importance of punctuality and

· marking timely attendance.

Interpret correctly legal, regulatory and ethical requirements specific to the apparel industry. Identify procedures to follow if legal,

· regulatory and ethical requirements of the organisation are not met. Carry out work functions in accordance with

· legislation and regulations, organizational guidelines and procedures. State customer specific requirements

· mandated as a part of the work process. State country/customer specific regulations for

· the apparel sector and their importance. State reporting procedure of the organization

·

in case of deviations. State limits of personal responsibility

.· Identify and report any possible deviation to

· regulatory requirements. Seek and obtain clarifications on policies and

· procedures, from the supervisor or other authorized personnel. Apply and follow the organisational policies

· and procedures within limits of self-authority. Provide support to the supervisor and team

·

members in enforcing the organisational considerations.

Explain the importance of effective

· communication. Communicate effectively with others.

· Identify and follow personal grooming and

· hygiene. Follow organization procedures and maintain

· personal health and hygiene and avoid habits like ghutka, tobacco etc. Interact effectively in a group.

· Manage time effectively

.·

Explain the importance of resume and

· prepare your resume. Prepare for interviews.

Unique Equipment Required:-

surplus fabric is used quantity and quality may vary as per requirement), trims (the quantity and variety may vary as per requirement), stools , cutting table, “teacher’s table, & chair “, vacuum pressure , disposable die cutting pad/clicker pads, thin plastic film(quantity may vary), polyoverlay/poly sheeting(quantity may vary), paper separating tissue(quantity may vary), kraft underlay (quantity may vary),

spray adhesives (quantity may vary),straight pins (quantity may vary), fabric roll stand , rubber moulded layer weight (the quantity and variety may vary), cloth clamp (the quantity and variety may vary), drills and thread markers, masking tapes (the quantity and variety may vary), count ticket (quantity may vary),m bundled tickets (quantity may vary), tie-ups bundle ties , protective equipments (nose mask, stainless steel mesh gloves etc.

The quantity may vary), cutting equipments (eg: straight knife , round knife etc, quantity may vary), fabric cutting scissors (metal), bundle hooks (thequantity may vary as per requirement), cutwork bags, rubber band (the quantity may vary as per requirement)

, marking pencil (graphite pencils quantity may vary as per requirement), marking pen, component list (for number of components needed for production),fabric consumption list (the amount of fabric needed), cut plan document (hard copy), style sheet (provided by buyer),

tech pack (provided by buyer), breakdown report (the quantity may vary as per requirement), samples of apparel , scales, measuring tape, fabric defect swatch file, types of lays study material, fabric swatch file, machine oil, first aid box & fire extinguisher,

made-ups and home furnishing samples, job card , stock book, order sheet, job card, dustbin, white board/ black board, marker (according to the training and job role), duster, students manual/notes, “students chairs ,with table arms”, basic stationary

Personal Attributes:- The candidate should have aptitude for conducting training, pre /post work to ensure competent, employable candidates at the end of training. Strong communication skills, interpersonal skills, ability to work as team;

diligent and is passionate for maintaining the quality in content and training delivery methodology. Candidate should have basic understanding of English language; however, this should not be a restrictive criterion as long as the candidate is willing and open to learn. He/she must be able to speak, read and write in the local language.

Experience:-

• The candidate should be 10th pass with six years supervisory experience in relevant trade • Certificate of minimum six months duration in relevant trade with 4 years of work experience in relevant trade

• Diploma of minimum 1 year duration in the relevant trade with 2 years of work experience in relevant trade

• ITI in relevant trade with minimum 2 years of work experience in relevant trade

• Graduation in relevant trade with minimum 2 years of work experience in relevant trade,

• He should be able to communicate in English and local language. He should have knowledge of equipment, tools, material, Safety, Health & Hygiene.

Plan and Prepare the process of cutting fabrics as per the job card receive:-

PC1. Check the fabrics for defects for severity and quantity like holes, stains, slubs, missing pick, etc

PC2. Calculate the number of components to be cut for a particular style as per job card

PC3. Calculate the quantity of fabrics needed against the job card received

PC4.Check for marker types as per fabric lay forms

PC5. Lay the fabrics in such a way so as to ensure the wastages is within defined tolerance

PC6. Spread the marker on the lay

Cut fabrics as per plan received from production planning:-

PC1. Ensure the fabric lays are clipped at suitable points to restrict sliding of fabric layers during cutting

PC2. Cut the fabric layers manually or with electrically operated cutting equipments like band knife, straight knife, etc. as per mentioned in the job card

PC3. Identify the cut parts, count tickets and then group them well to pass on

PC4. Ensure the bundled tickets have all the necessary information like style number, cut piece name, etc.

Comply with industry, regulatory and organizational requirements:-

PC1. Carry out work functions in accordance with legislation and regulations, organizational guidelines and procedures

PC2. Seek and obtain clarifications on policies and procedures, from your supervisor or other authorized personnel

PC3. Apply and follow these policies and procedures within your work practices

PC4. Provide support to your supervisor and team members in enforcing these considerations

PC5. Identify and report any possible deviation to these requirements